When you want to solve any problem and want to eliminate the cause of the problem completely, you need strong problem solving tool such as 8d problem solving. And to analyze the root cause of the problem, you need something called 5 why analysis root cause tool that helps to find the most pin pointed root cause, so that you can take the necessary action to eliminate the problem permanently.

Along with 8D analysis tool, the A3 report is also considered to be one of the best problem solving tools of all time, which is now being used by many industries as both helps to effectively solve the problem. The 5 why analysis is the one that sits in the heart of both the problem solving tools, wherein you can identify the root cause and eliminate.

It all starts with a simple question, you know the problem, but you don’t know how to solve it? No matter how big or how small is your problem, the 5 why analysis tool helps to solve your problem effectively by allowing you to easily identify various causes so that you can eliminate the same.

There is no time or date for the problem to occur, it can suddenly happen or arise at any time in any process of your company or business. The problems are bound occur, especially when you think of boosting your business. Most of the problems are symptoms of very deeper issues, which can create a chaos on a later stage without your knowledge.

But you may ask us, how can it be so when you can easily and quickly fix the problem with a simple solution. Well, yes you will provide the solution, but is it a temporary fix or a permanent fix? Obviously, its a temporary fix and problem will arise again and again in the same way or in other different form when you are not fixing it permanently. That’s why you need a root cause analysis tool that helps you to solve the problem permanently and effectively. One such tool is the 5 why analysis root cause identification tool.

Contents

- 1 What is 5 Why Analysis Root Cause?

- 2 Origin of 5 Whys Analysis Tool And Why You Should Use 5 Why Technique?

- 3 How To Use 5 Why Analysis Tool?

- 4 When To Use 5 Why Analysis?

- 5 Factors to keep in mind while conducting 5 Whys Analysis

- 6 57 Examples of 5 Why Analysis

- 6.1 Example 1:

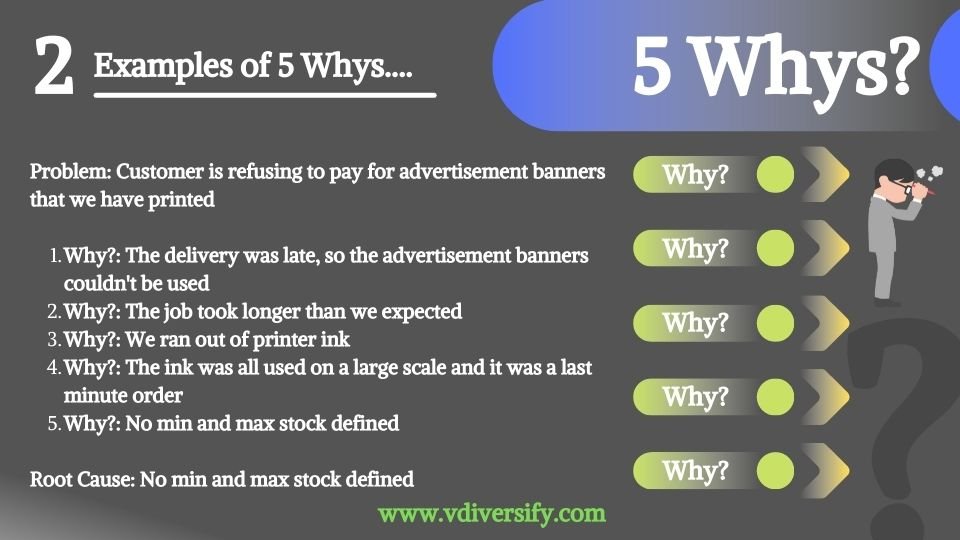

- 6.2 Example 2:

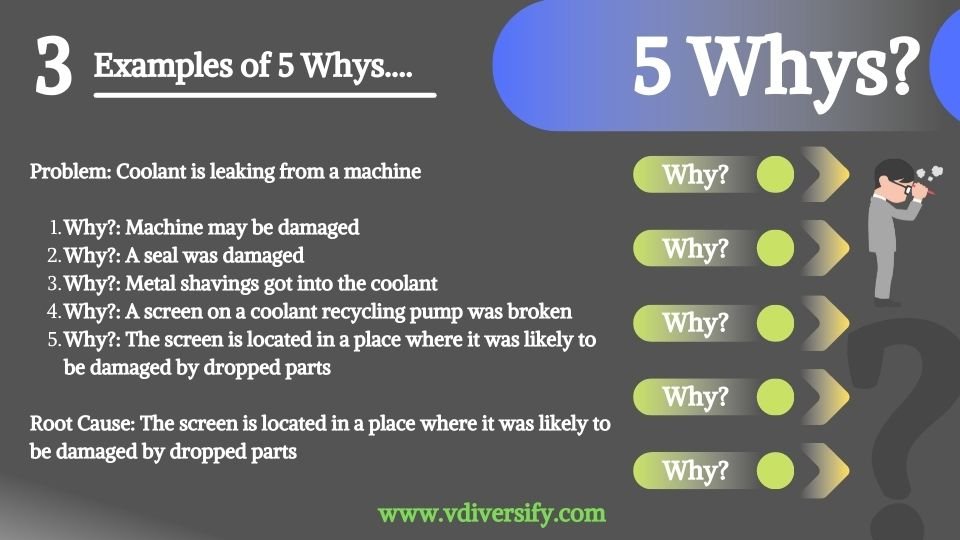

- 6.3 Example 3:

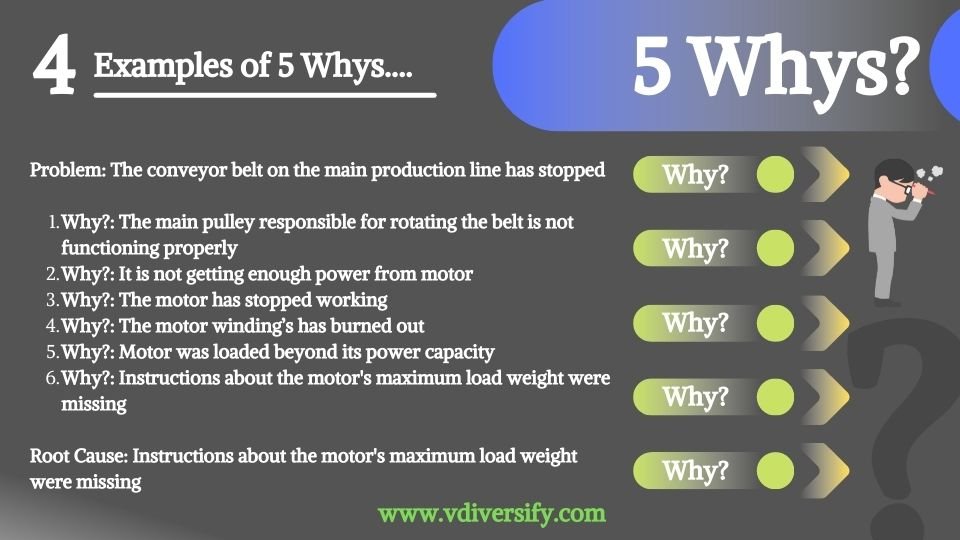

- 6.4 Example 4:

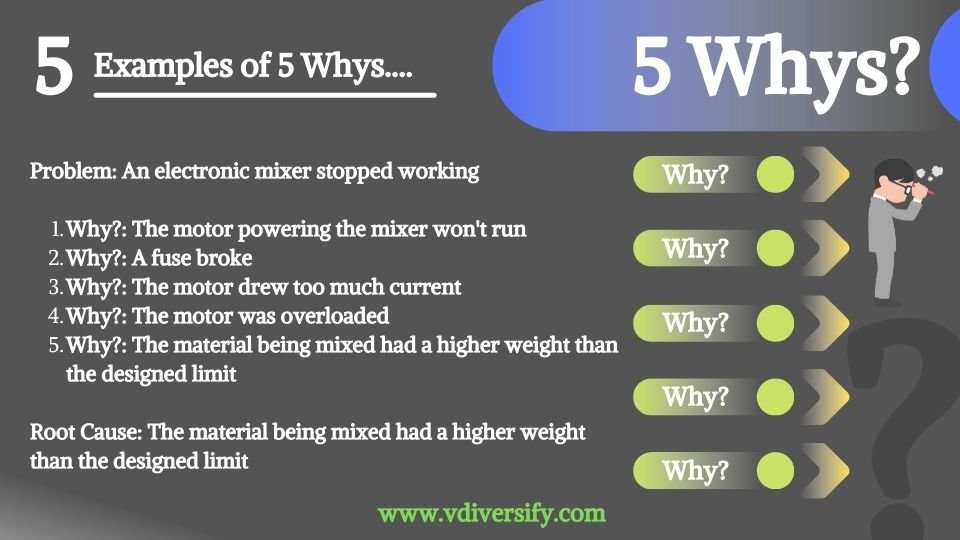

- 6.5 Example 5:

- 6.6 Example 6:

- 6.7 Example 7:

- 6.8 Example 8:

- 6.9 Example 9:

- 6.10 Example 10:

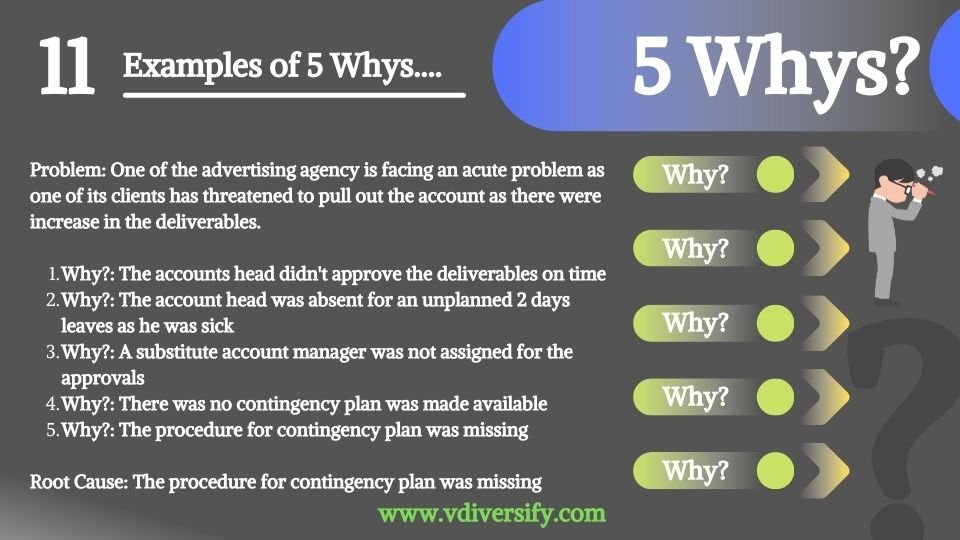

- 6.11 Example 11:

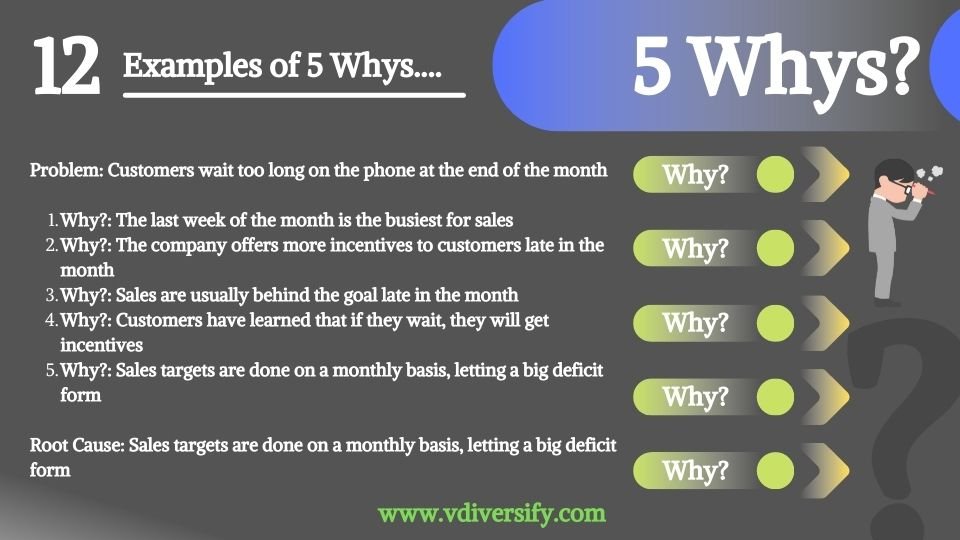

- 6.12 Example 12:

- 6.13 Example 13:

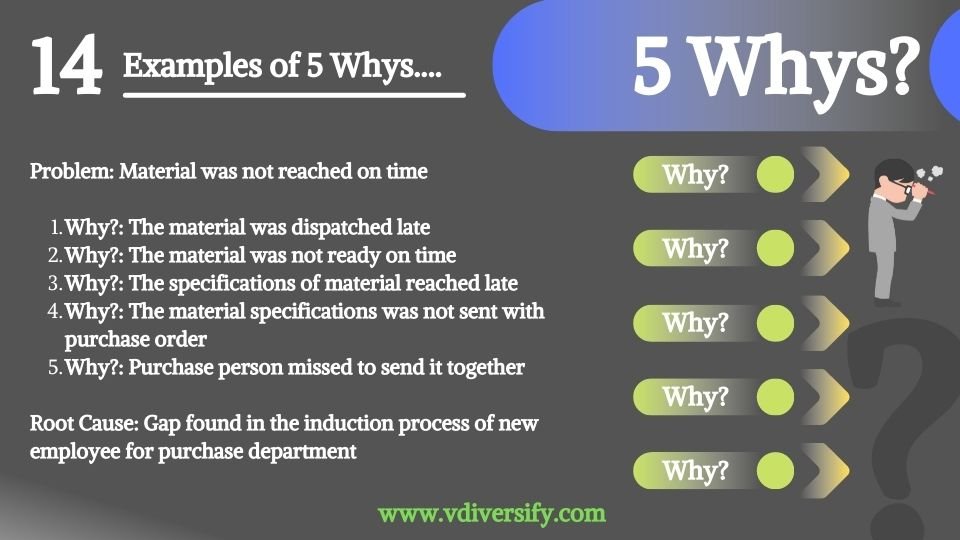

- 6.14 Example 14:

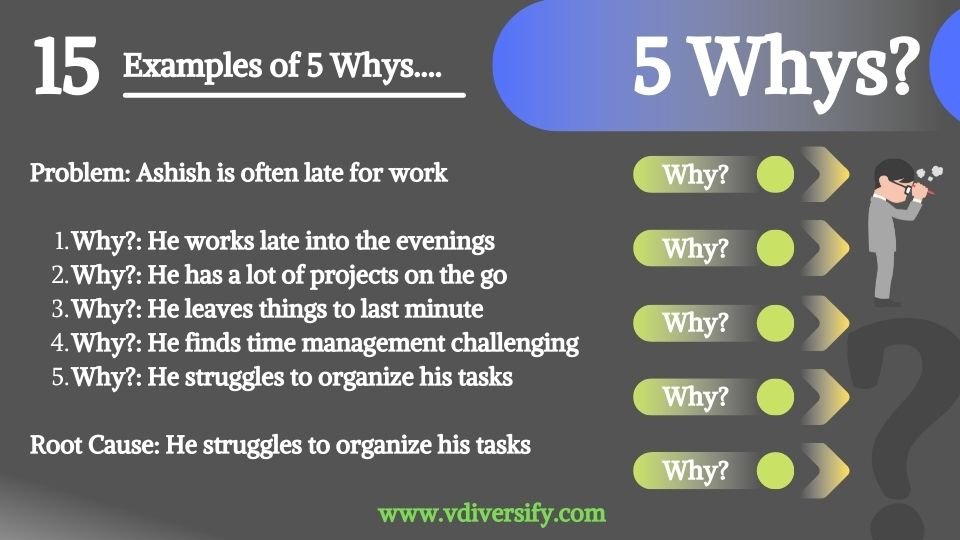

- 6.15 Example 15:

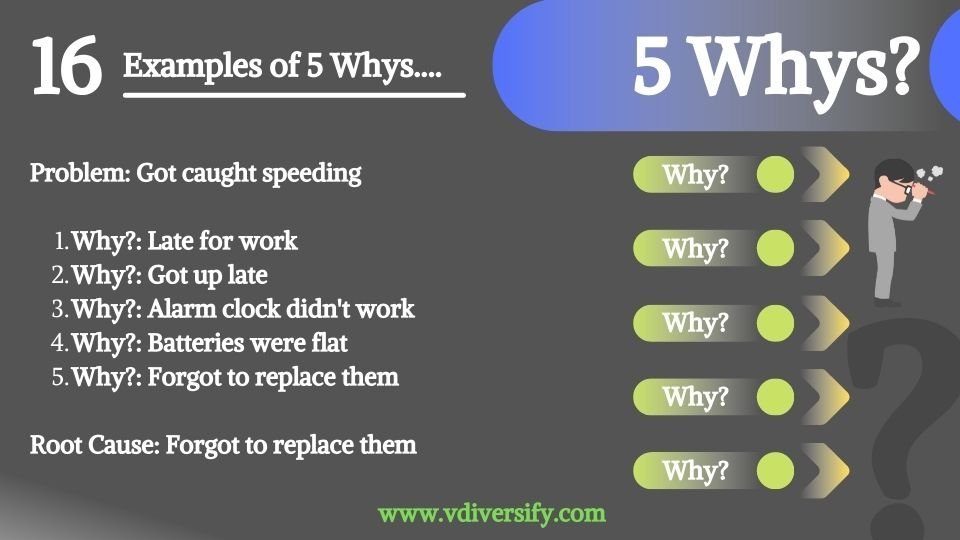

- 6.16 Example 16:

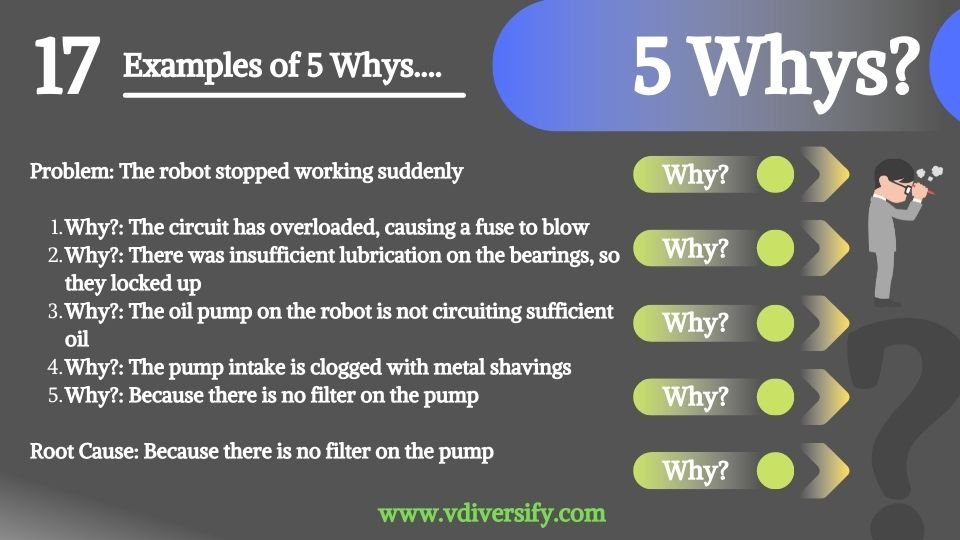

- 6.17 Example 17:

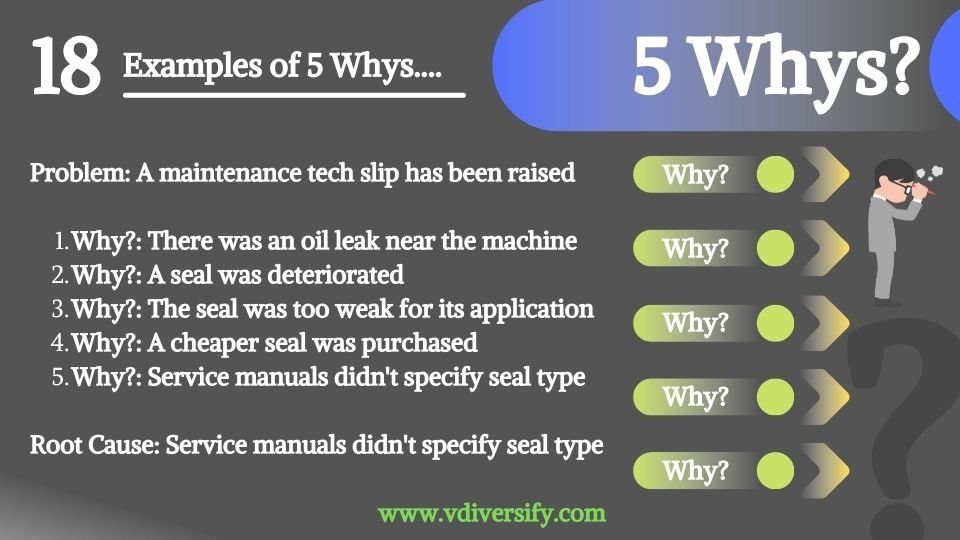

- 6.18 Example 18:

- 6.19 Example 19:

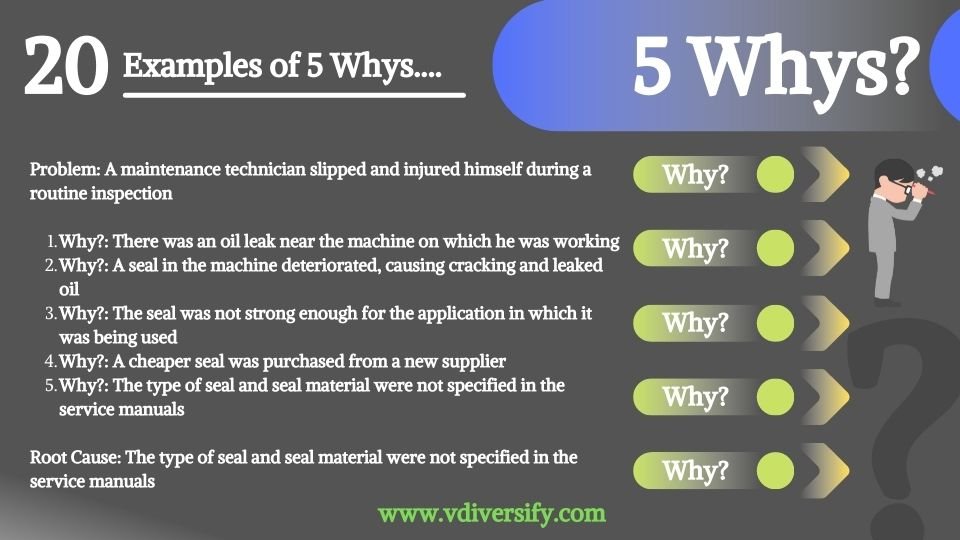

- 6.20 Example 20:

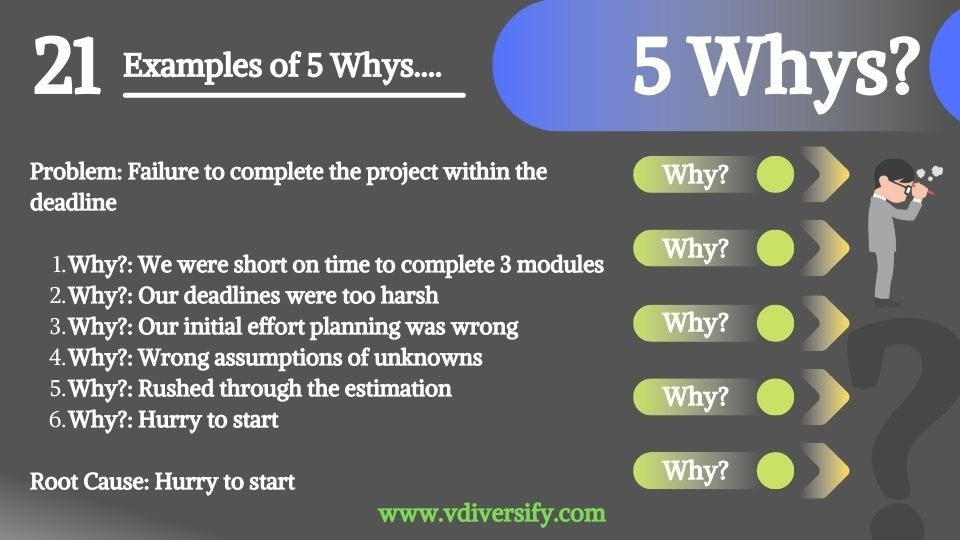

- 6.21 Example 21:

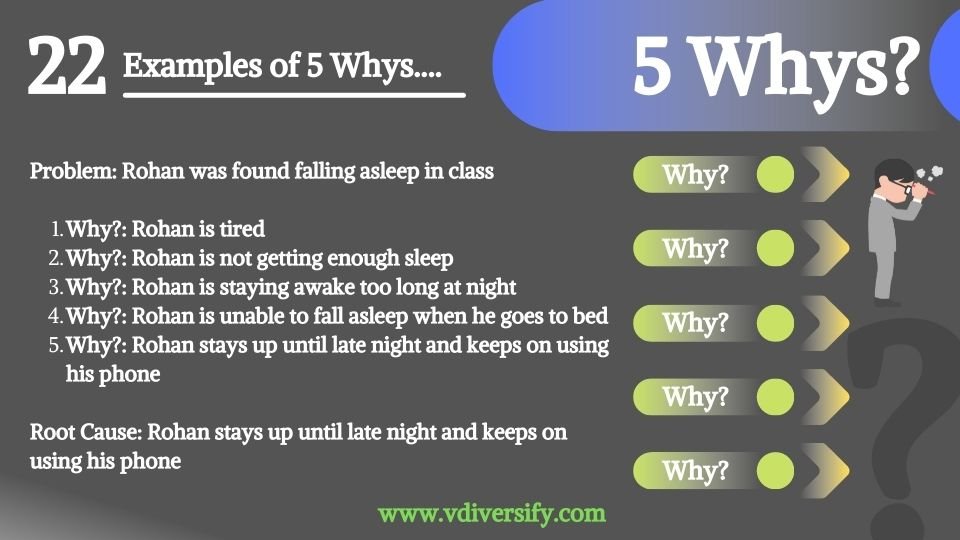

- 6.22 Example 22:

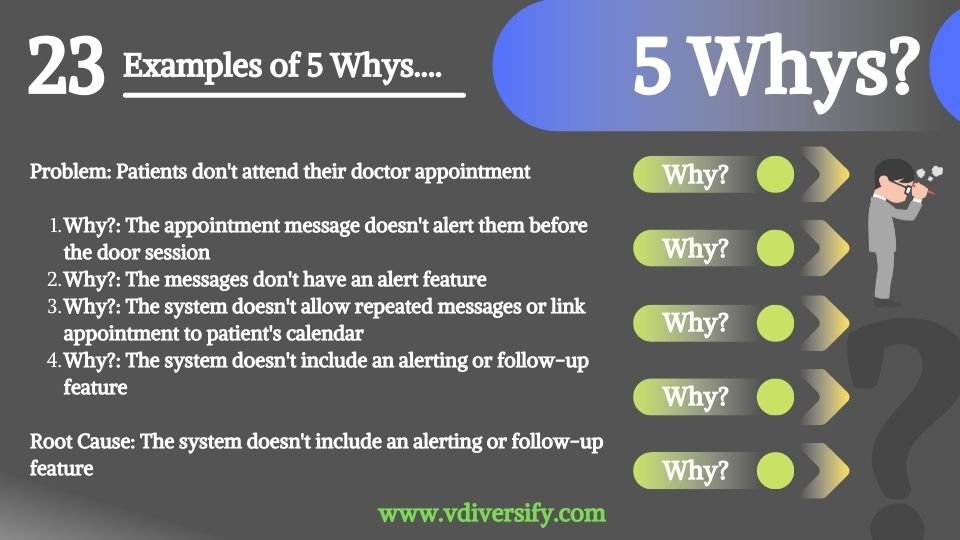

- 6.23 Example 23:

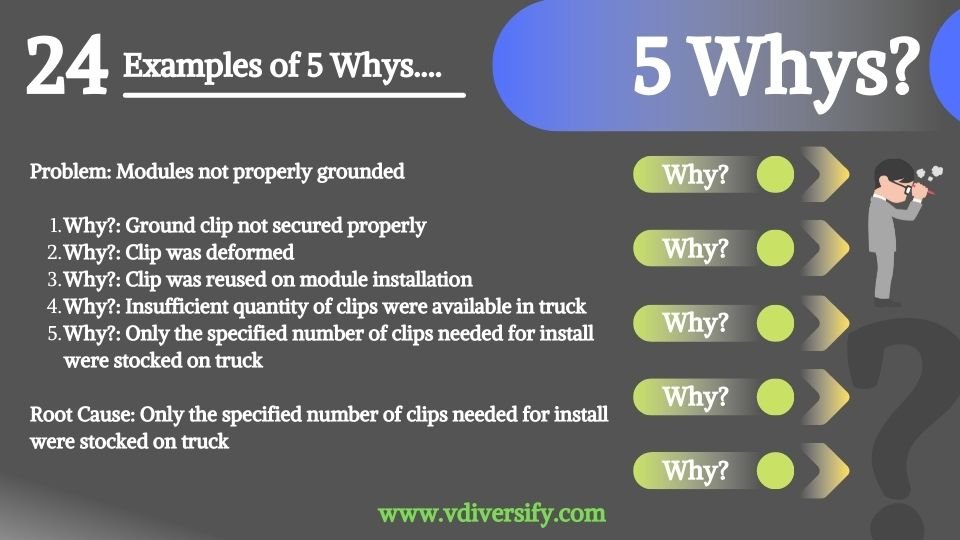

- 6.24 Example 24:

- 6.25 Example 25:

- 6.26 Example 26:

- 6.27 Example 27:

- 6.28 Example 28:

- 6.29 Example 29:

- 6.30 Example 30:

- 6.31 Example 31:

- 6.32 Example 32:

- 6.33 Example 33:

- 6.34 Example 34:

- 6.35 Example 35:

- 6.36 Example 36:

- 6.37 Example 37:

- 6.38 Example 38:

- 6.39 Example 39:

- 6.40 Example 40:

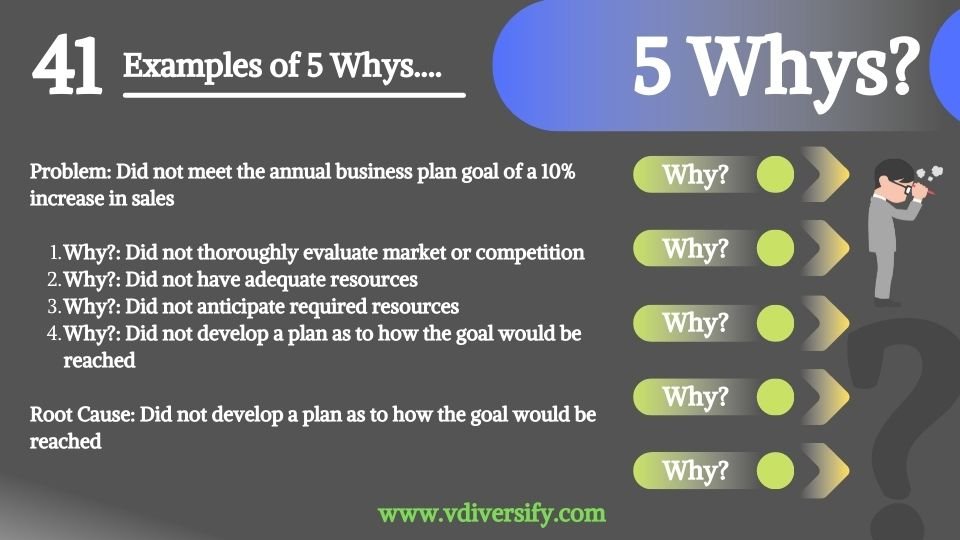

- 6.41 Example 41:

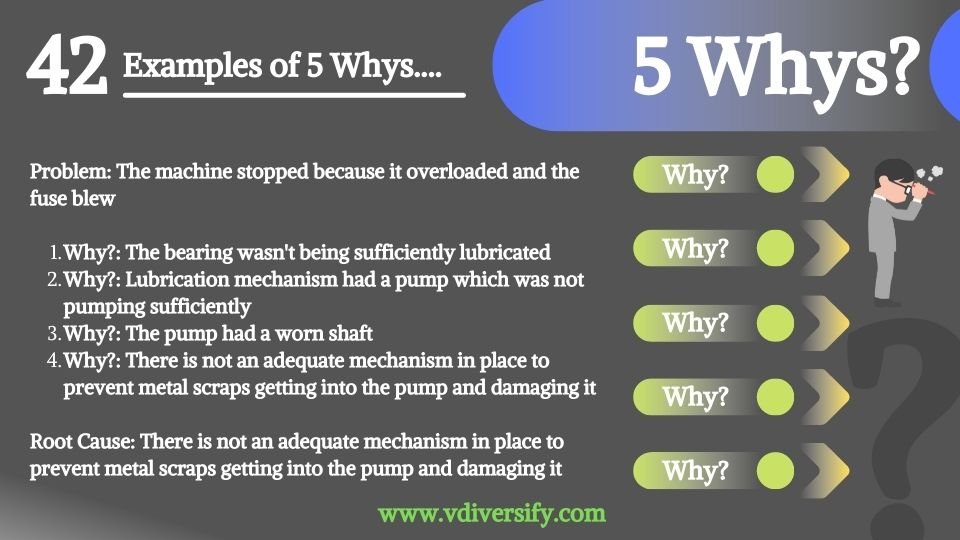

- 6.42 Example 42:

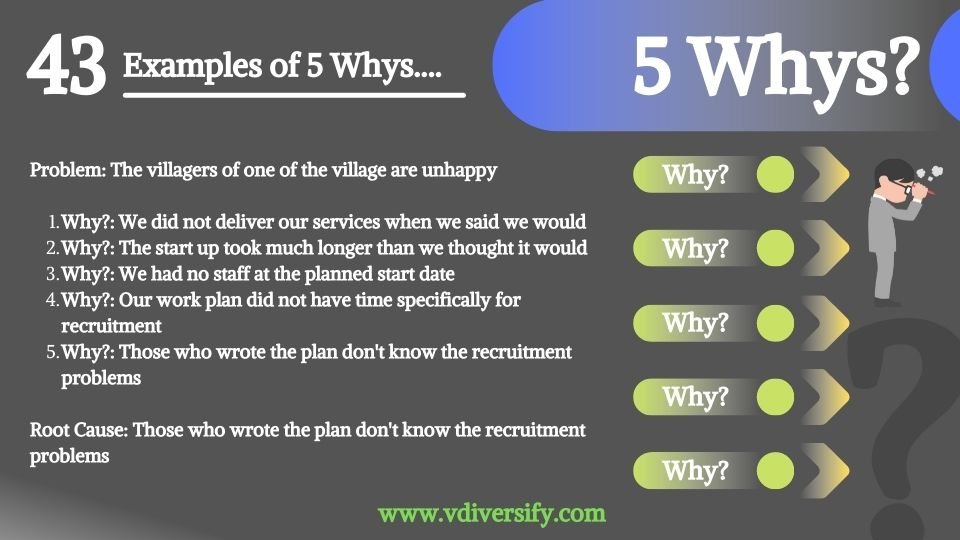

- 6.43 Example 43:

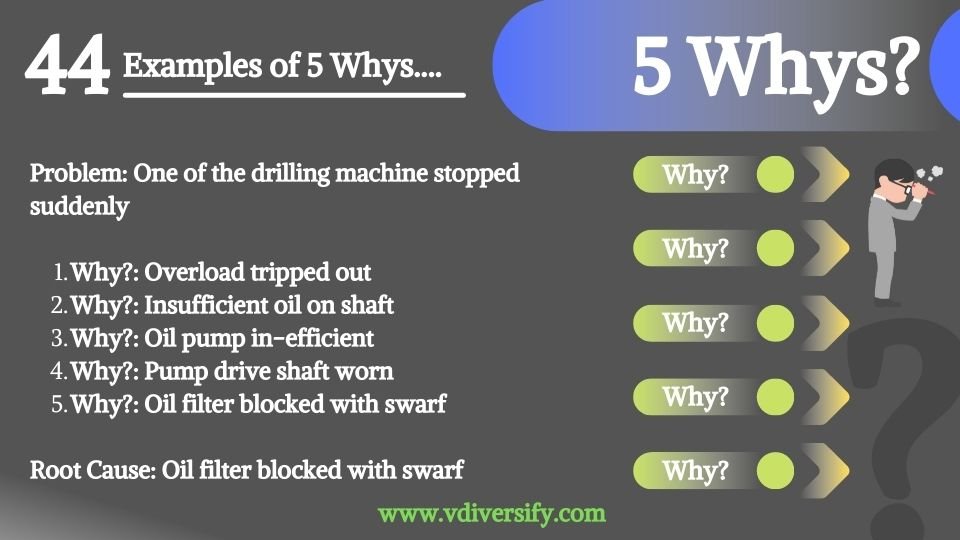

- 6.44 Example 44:

- 6.45 Example 45:

- 6.46 Example 46:

- 6.47 Example 47:

- 6.48 Example 48:

- 6.49 Example 49:

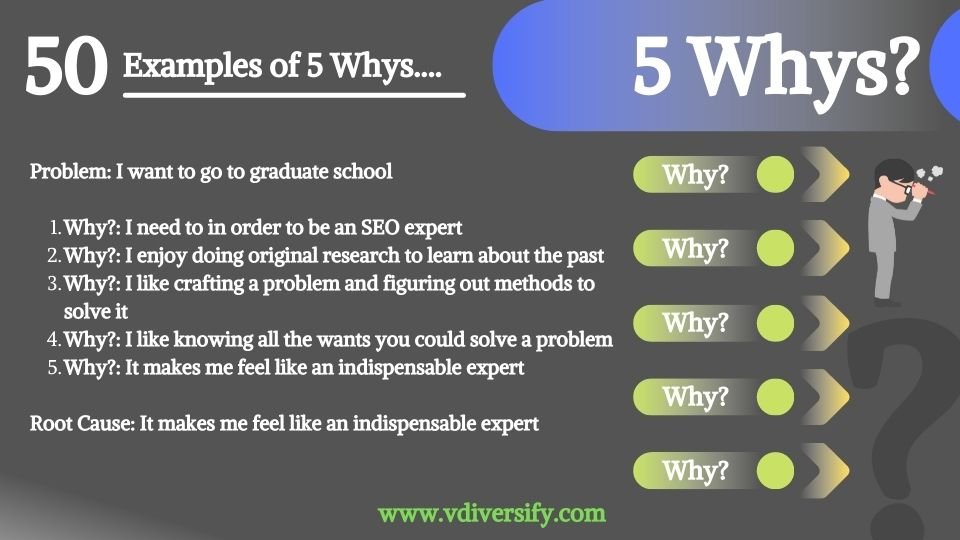

- 6.50 Example 50:

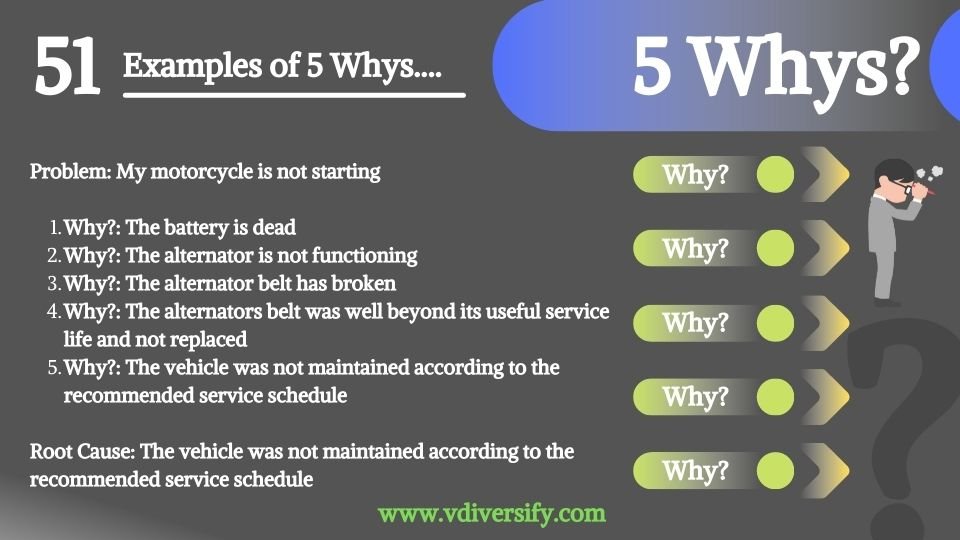

- 6.51 Example 51:

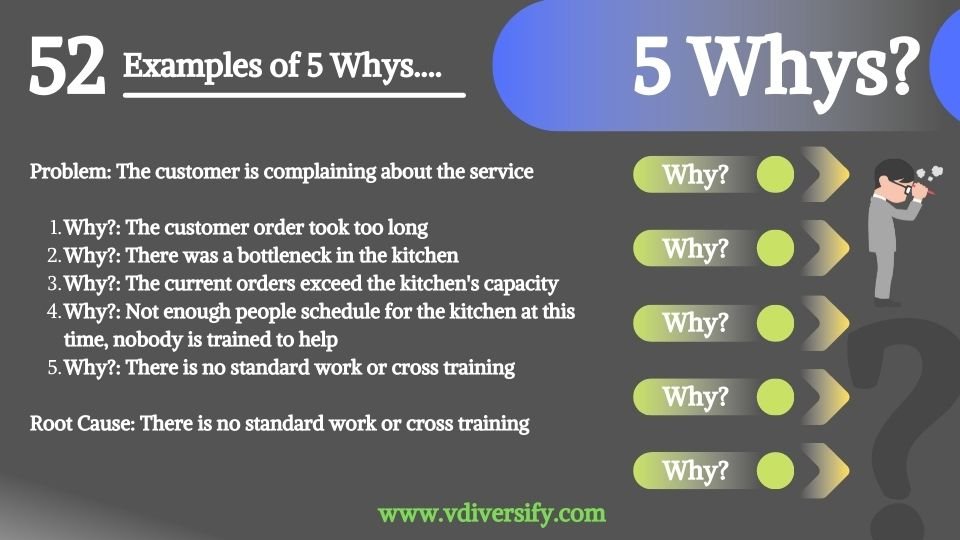

- 6.52 Example 52:

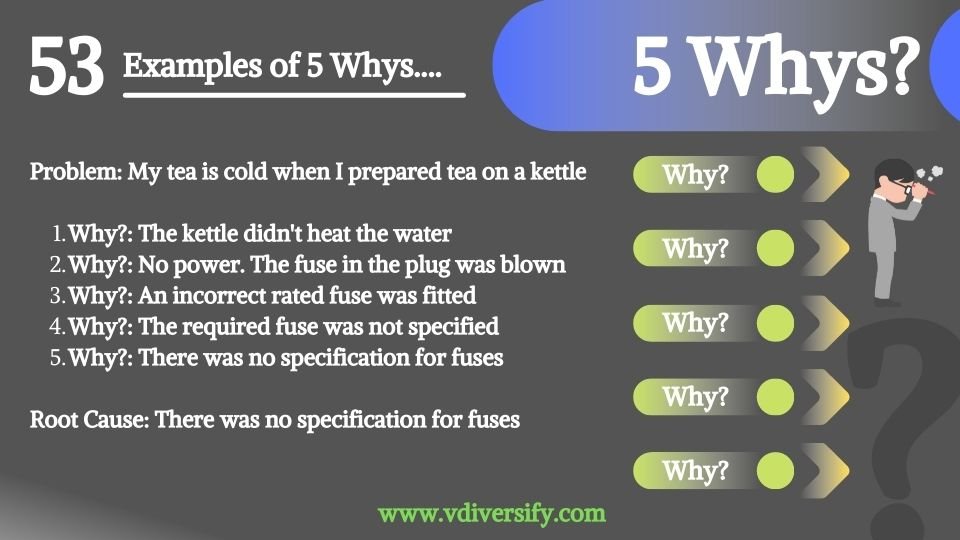

- 6.53 Example 53:

- 6.54 Example 54:

- 6.55 Example 55:

- 6.56 Example 56:

- 6.57 Example 57:

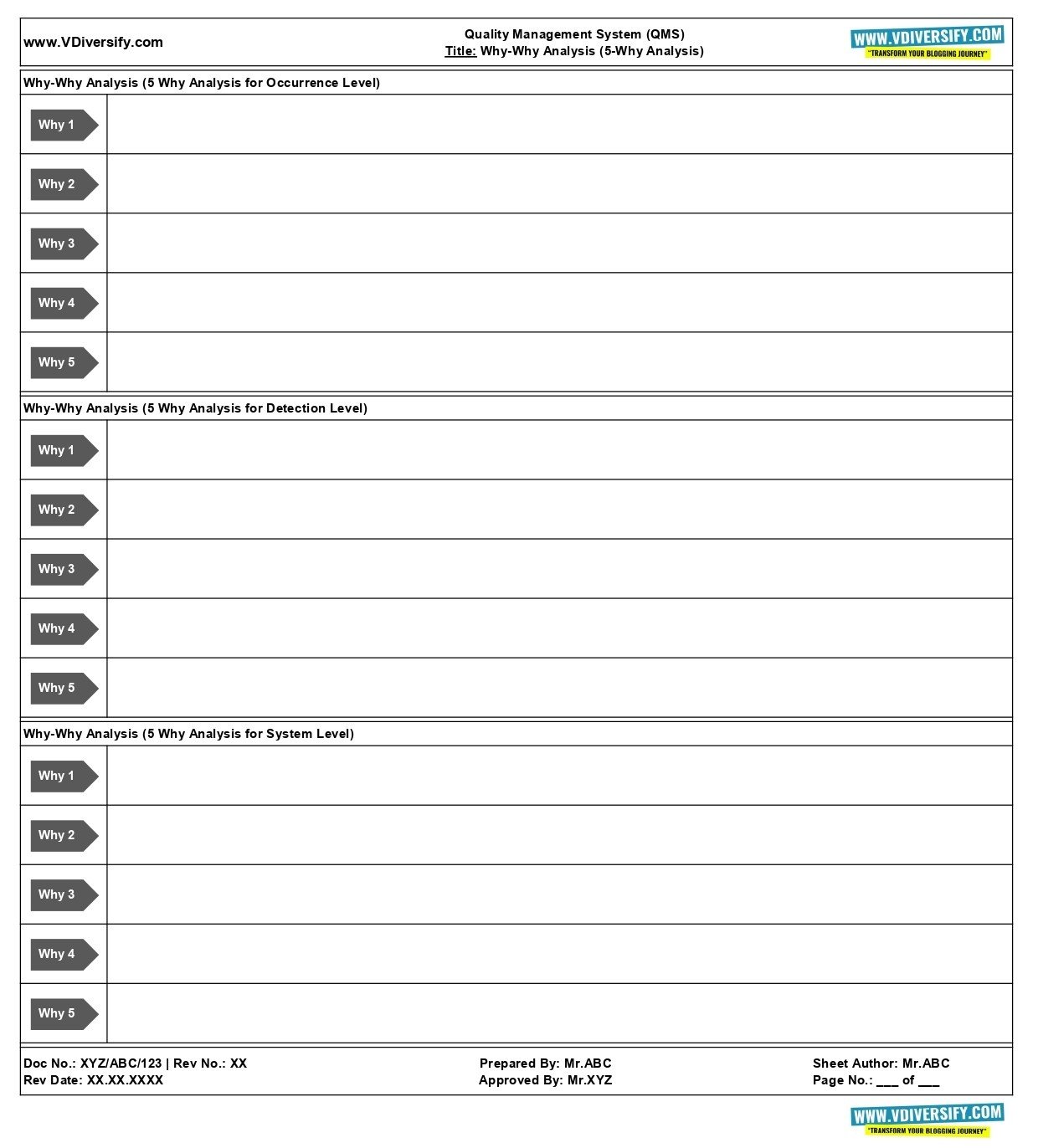

- 7 5 Why Analysis PDF and 5 Why Analysis Examples – Download Here

- 8 Conclusion

What is 5 Why Analysis Root Cause?

Definition of 5 Whys:

The 5 way technique is one of the most effective and most preferred root cause analysis tools in the world of problem solving, TQM, Lean Management, Six Sigma and so on. The 5 why tool effectively helps you to solve difficult of problems to the root by fixing all the causes with proper permanent corrective action that helps in preventing failures and mistakes recurring in future.

The five whys (5 whys) is a problem-solving tool or method that effectively solves a problem by making use of cause-and-effect diagram. The main goal of 5 whys is to find the root cause of a problem or a defect, by successfully asking the question why at-least 5 times in succession for every answer.

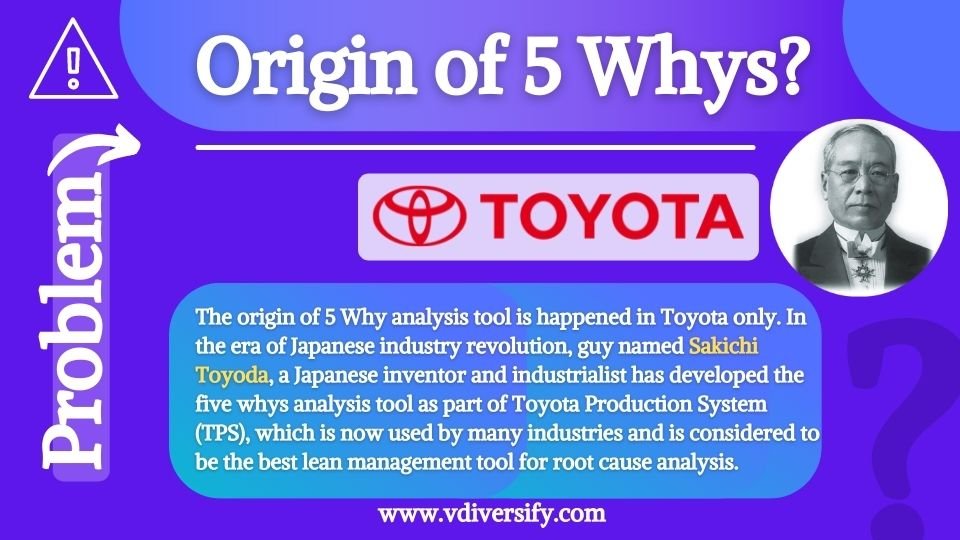

Origin of 5 Whys Analysis Tool And Why You Should Use 5 Why Technique?

All of us have already heard about Toyota. The origin of 5 Why analysis tool is happened in Toyota only. In the era of Japanese industry revolution, guy named Sakichi Toyoda, a Japanese inventor and industrialist has developed the five whys analysis tool as part of Toyota Production System (TPS), which is now used by many industries and is considered to be the best lean management tool for root cause analysis.

The Toyota has made it mandatory to ask Why five times whenever there is a problem. For every problem, one must respond with 5 whys until the final root cause is found. This helped Toyota to solve every problem including the most complex ones effectively and efficiently. Once the root cause is found, the Toyota was able to take the necessary permanent corrective actions to irradiate the problem once and for all. This strategy of 5 whys helped in improve the production efficiency drastically.

The Toyota Production System was focused on the successful implementation of 5 why strategy, wherein the team was able to focus on the problem on shop floor rather than the problems on the desks or meeting rooms. With this the decision making of the team was drastically improved with a key focus on processes by understanding what actually is happening in the shop floor.

Thus, the 5 why root cause analysis must be conducted along with the CFT including all process owners and operators. The one who is working on the shop floor, knows better than the ones who is working on meeting rooms. Operators always have a practical experience and knowledge who can give you the actual insights including the most valuable inputs. If required the CFT should also visit the shop floor to analyze the problem practically.

How To Use 5 Why Analysis Tool?

Remember, the 5 why analysis must be conducted by CFT along with Operators too. The CFT must contain all the key stakeholders including Process Owners and Subject Matter Experts (SME’s) too. The more the team is experienced, the problem solving with 5 why analysis is going to be more effective.

The 5 Why tool helps you identify the gray areas or the hidden causes that are really playing the role in development of problem. Thus, the 5 whys will show you the actual source of the problem with which you can effectively implement the corrective actions.

Most of the times when you address a problem, you will often say that it is a human error. But when you actually dive deeper in the root cause analysis, you will come to know that, it is either a process error, system error or the technical error. Only by fixing these causes you can able to nullify the problem. If you just fix the human errors, its never going to solve the actual root problem.

How to use the 5 why analysis root cause:

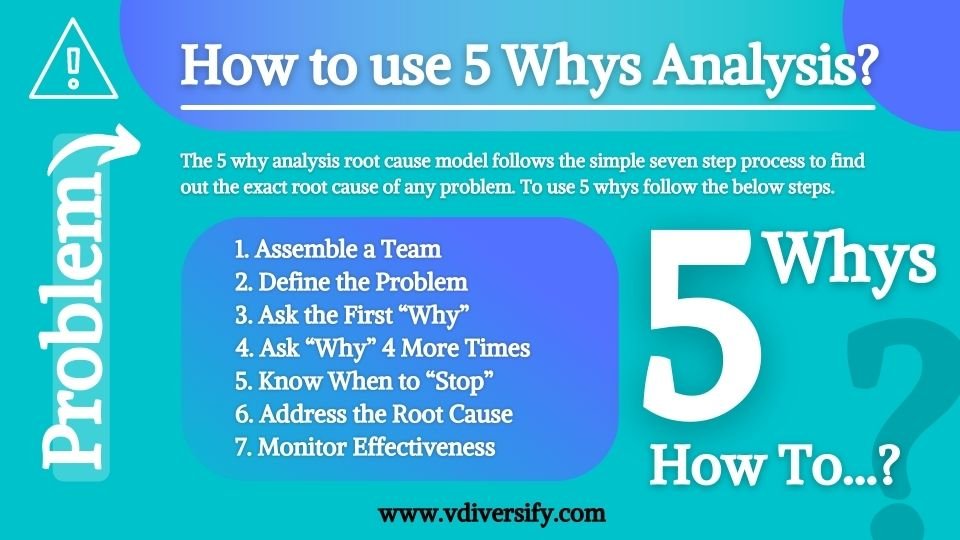

The 5 why analysis root cause model follows the simple seven step process to find out the exact root cause of any problem. To use 5 whys follow the below steps.

1. Assemble a Team

Remember, the first step in using a 5 whys analysis is to assemble a team of subject matter experts (SME’s). The subject matter expertise can be also called as cross-functional team (CFT) or multi-disciplinary team.

The CFT team must contain all the key stakeholders or the process owners or the key users from all key functions, such as Quality, QMS, Production, Assembly, Project Management, Engineering, Purchase, Supply Chain, Logistics, Stores, Warehouse or Dispatch, and so on.

The team must contain a Champion who is the master in problem solving or in systems, such as from QMS. There should also be a Leader who is going to lead the 5 why analysis from starting to until the counter measures are in place and closed. Champion will ensure that he supports the team and leader with all kinds of tools, countermeasures and decision making.

Choosing a team that is relevant to the problem is very much important. If necessary, you can also involve Operators, Customers, and Suppliers as and when required to completely eliminate the problem.

2. Define the Problem

Defining the problem description is one of the important parts of five why analysis. A problem description is the one that helps you clearly identify the root cause through 5 why analysis. Hence, sit with a CFT team and write down a clear problem description that helps you step on to the process of why why analysis.

For example, a clear written problem description could be, “Team Flash isn’t meeting its response time targets” or “Software release team Arrow resulted in too many rollback failures”. A problem statement written like this will help you conduct why why analysis and eliminate the root cause easily.

3. Ask the First “Why”

The process of 5 why why analysis starts with asking the first why. For this a leader of CFT can ask the team why the problem has occurred? or why the problem is occurring? For example, the leader can ask, “why isn’t team Flash meeting its response time targets?”.

You may think, asking why sounds very simple, but on a serious note answering the why takes a serious thought. The intention here is to find out the answers that are hidden under beneath the ground that have actually happened that are held responsible and accountable. These answers are the ones that cause the actual problem. Make sure that there aren’t any guesses, such as could have happened, might have happened, and so on.

By doing this way you can able to identify multiple causes of a problem that may create the problem again. To find out such multiple causes you can use, fish bone diagram, that allows you to get down to the multiple causes around 6M’s (Man, Machine, Method, Material, Measurement, and Mother Nature).

4. Ask “Why” 4 More Times

For each of the answers that are generated from the first why, must be further asked with whys at-least 4 more times in succession, so that you can get down to the bottom of the root cause. For every answer, frame another question in response for the answer that you have received.

A question followed by an answer will allow you to get down to the bottom of root cause. If there are multiple causes then ask whys for each one of them at-least 4 times in a row, until you get down to the bottom of the root cause until there are no further answers.

5. Know When to “Stop”

Another important factor that must be considered when you are conducting why why analysis is that, know when to stop asking why. In simple terms, you need to stop asking why when there are no more whys are not left, no useful responses are produced, and cannot go any further. Generally, a why why analysis ends at 5 whys. Sometimes this can go up to 6 whys.

6. Address the Root Cause

Once you have found the root cause, its time to lay down a corrective action or counter-measure followed by a permanent corrective action. Additionally, you can also implement horizontal deployment along with counter-measures for other whys too. Knowing when to stop asking why will allow you to find the perfect root cause to eliminate the problem.

7. Monitor Effectiveness

Once you have completed the 5 why analysis and implemented corrective actions along with horizontal deployment actions, now its time to measure and monitor the effectiveness of corrective actions. The effectiveness must be monitored at-least for 3 months or for 3 dispatches or as per customer requirements and the severity of the problem.

To measure the effectiveness you can use the effectiveness monitoring template and must be measured by CFT or the process owners on a inter-changed departments. You can also conduct layered process audits to measure the effectiveness of implemented actions.

When To Use 5 Why Analysis?

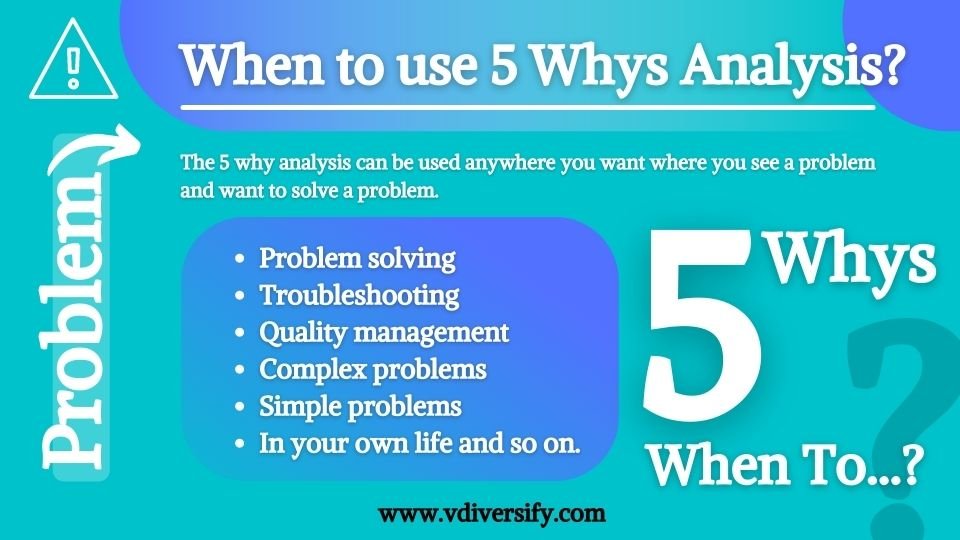

The 5 why analysis can be used anywhere you want where you see a problem and want to solve a problem. It can be used in any type of businesses and industries such as, Automotive, IT Software, IT Services, Healthcare, Aviation, Banking, Agriculture, Military, Space, Telecommunication, Manufacturing, Electronics, and so on. Hence, use 5 whys analysis for,

- Problem solving

- Troubleshooting

- Quality management

- Complex problems

- Simple problems

- In your own life and so on.

However, when the problem is more complex and there are chances of multiple causes, then you need to conduct 5 why analysis along with cause and effect diagram or a failure mode effective analysis (FMEA) to address multiple probable causes effectively. You can also use an is or is not sheet to get better results in writing down the problem and effectively solving the problem.

Factors to keep in mind while conducting 5 Whys Analysis

When you are conducting 5 why root cause analysis you must remember the following factors that impacts the 5 why problem-solving analysis. Treat these factors as the advice for why why analysis.

Advice to conduct 5 why analysis:

- A CFT must conduct the 5 why analysis

- All process owners and key stakeholders including operators must be involved for the 5 why analysis

- Management must be involved and engaged in the discussion of root cause and implementing counter-measures

- A 5 why analysis is not an individual responsibility. The responsibility of conducting a 5 why analysis lies with CFT

- Try to use whiteboards or printed 5 why analysis format rather than computers for better results

- During why why analysis everyone must share their ideas for continual improvements

- A problem statement must be written very clearly and do not just get carried away. The problem must be understood by every member of CFT including operator

- Use cause and effect diagram for better results

- Make sure that you distinguish causes from symptoms

- Always pat attention to the logic of cause and effect diagram relationship

- Never blame the root cause as human error or an operator error

- Root cause must be solved systematically to eliminate the problem completely

- The answers against 5 whys must be more precise and sensible

- Never jump to root cause directly or make conclusions without any base

- The statements made must be based on brainstorm, knowledge, facts, and analysis

- Conduct the 5 why analysis step-by-step and not to rush

- The root cause must be targeted to the process and not the people

- Brainstorm, be sincere, share ideas, and trust each other

- Know exactly when to stop asking why, meaning when the answer for why has no more sense

57 Examples of 5 Why Analysis

The ultimate aim of 5 why analysis is to get to the root of the problem and then fit the problem based on the root cause identified. A root cause can be of two types, one being the detection root cause and the other being the occurrence root cause. The five why analysis allows you to go down to the bottom of problem which could be actually an unexpected problem.

A problem can be of anything. Basically, in businesses the problems are divided into a human problem or human error, process problem, product problem, and a system problem. You must always focus on to solving a problem systematically followed by other types of problems. Hence, it is very important eliminate the root cause systematically in order to not to repeat such problems in future.

Here are few of the examples of five why analysis that you can go through to have better understanding. The examples of 5 whys mentioned here are applicable for all types of industries, ranging from Automotive, IT, Healthcare, Medical, Digital Marketing, Online Businesses, Telecommunication, Software, and so on.

Example of 5 why analysis:

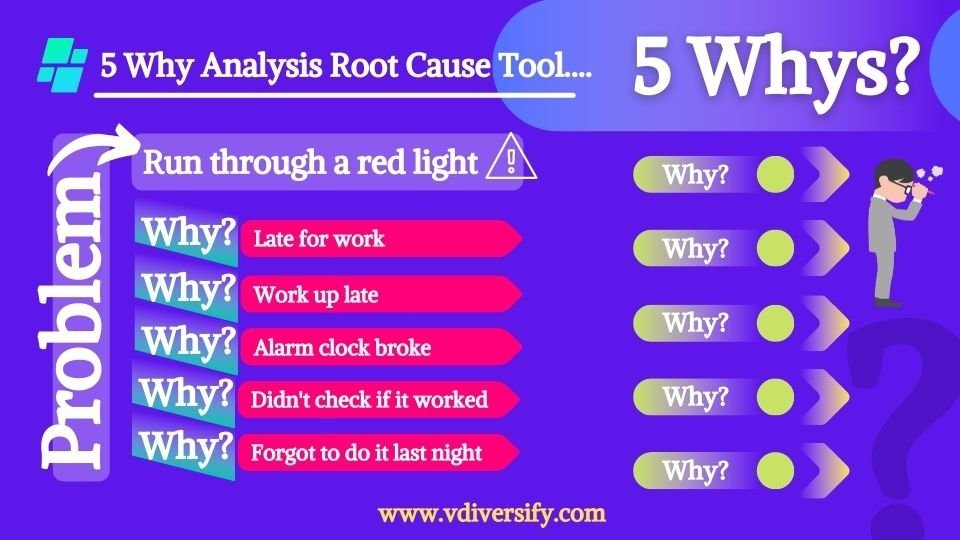

Here is the basic 5 why analysis example root cause that you can see that clearly explains how a five analysis is conducted.

Example 1:

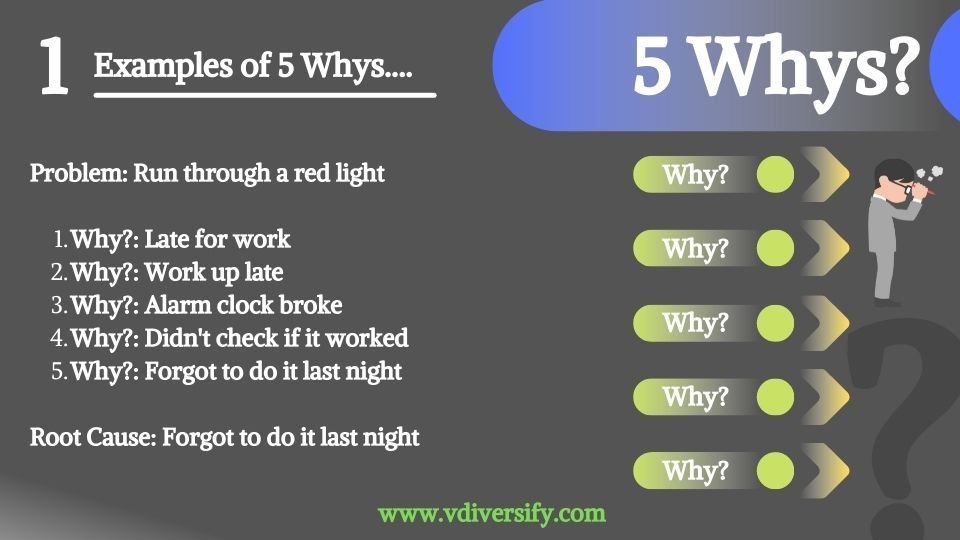

Problem: Run through a red light

Why?: Late for work

Why?: Work up late

Why?: Alarm clock broke

Why?: Didn’t check if it worked

Why?: Forgot to do it last night

Root Cause: Forgot to do it last night

Example 2:

Problem: Customer is refusing to pay for advertisement banners that we have printed

Why?: The delivery was late, so the advertisement banners couldn’t be used

Why?: The job took longer than we expected

Why?: We ran out of printer ink

Why?: The ink was all used on a large scale and it was a last minute order

Why?: No min and max stock defined

Root Cause: No min and max stock defined

Example 3:

Problem: Coolant is leaking from a machine

Why?: Machine may be damaged

Why?: A seal was damaged

Why?: Metal shavings got into the coolant

Why?: A screen on a coolant recycling pump was broken

Why?: The screen is located in a place where it was likely to be damaged by dropped parts

Root Cause: The screen is located in a place where it was likely to be damaged by dropped parts

Example 4:

Problem: The conveyor belt on the main production line has stopped

Why?: The main pulley responsible for rotating the belt is not functioning properly

Why?: It is not getting enough power from motor

Why?: The motor has stopped working

Why?: The motor winding’s has burned out

Why?: Motor was loaded beyond its power capacity

Why?: Instructions about the motor’s maximum load weight were missing

Root Cause: Instructions about the motor’s maximum load weight were missing

Example 5:

Problem: An electronic mixer stopped working

Why?: The motor powering the mixer won’t run

Why?: A fuse broke

Why?: The motor drew too much current

Why?: The motor was overloaded

Why?: The material being mixed had a higher weight than the designed limit

Root Cause: The material being mixed had a higher weight than the designed limit

Example 6:

Problem: The vehicle will not start

Why?: The battery is dead

Why?: The alternator is not functioning

Why?: The alternator belt is broken

Why?: The alternator belt was well beyond its usual service life and not replaced

Why?: The vehicle was not maintained according to the recommended service schedule

Root Cause: The vehicle was not maintained according to the recommended service schedule

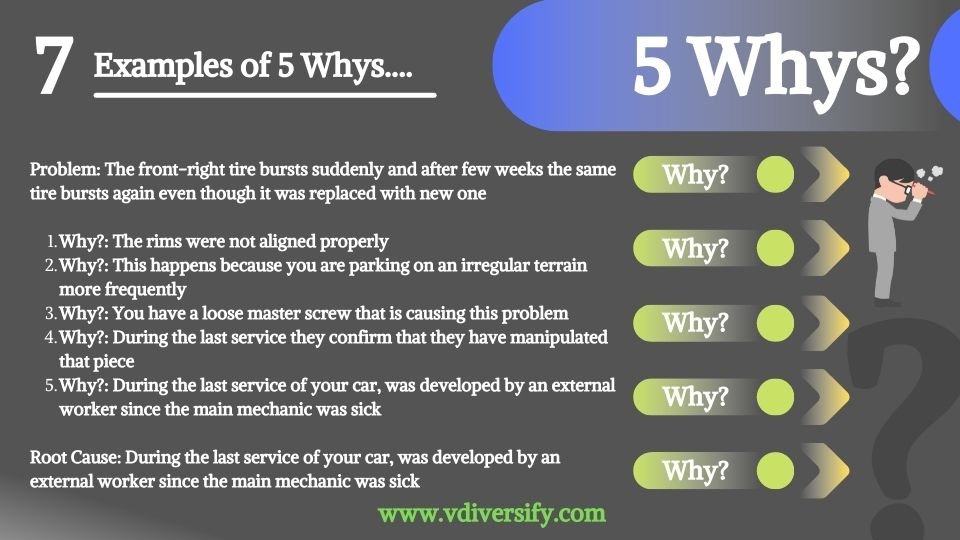

Example 7:

Problem: The front-right tire bursts suddenly and after few weeks the same tire bursts again even though it was replaced with new one

Why?: The rims were not aligned properly

Why?: This happens because you are parking on an irregular terrain more frequently

Why?: You have a loose master screw that is causing this problem

Why?: During the last service they confirm that they have manipulated that piece

Why?: During the last service of your car, was developed by an external worker since the main mechanic was sick

Root Cause: During the last service of your car, was developed by an external worker since the main mechanic was sick

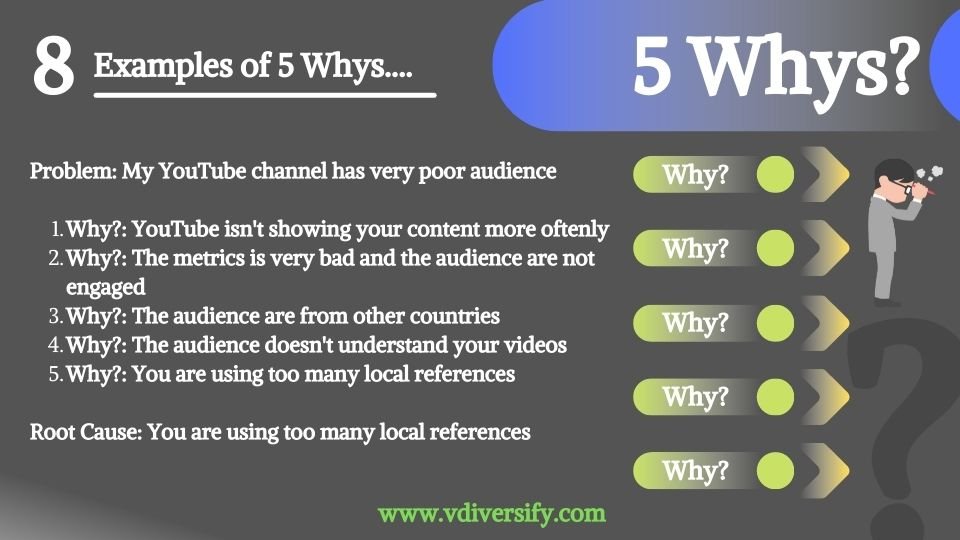

Example 8:

Problem: My YouTube channel has very poor audience

Why?: YouTube isn’t showing your content more oftenly

Why?: The metrics is very bad and the audience are not engaged

Why?: The audience are from other countries

Why?: The audience doesn’t understand your videos

Why?: You are using too many local references

Root Cause: You are using too many local references

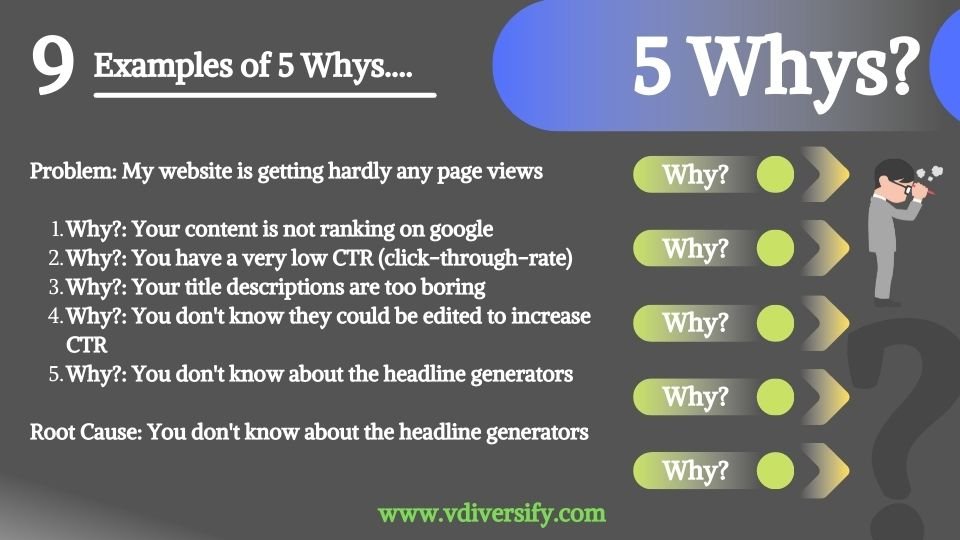

Example 9:

Problem: My website is getting hardly any page views

Why?: Your content is not ranking on google

Why?: You have a very low CTR (click-through-rate)

Why?: Your title descriptions are too boring

Why?: You don’t know they could be edited to increase CTR

Why?: You don’t know about the headline generators

Root Cause: You don’t know about the headline generators

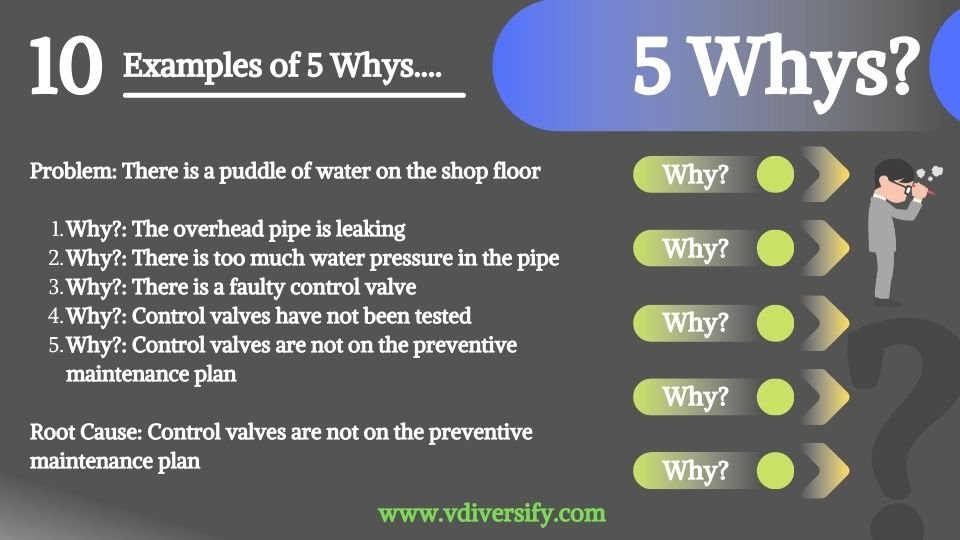

Example 10:

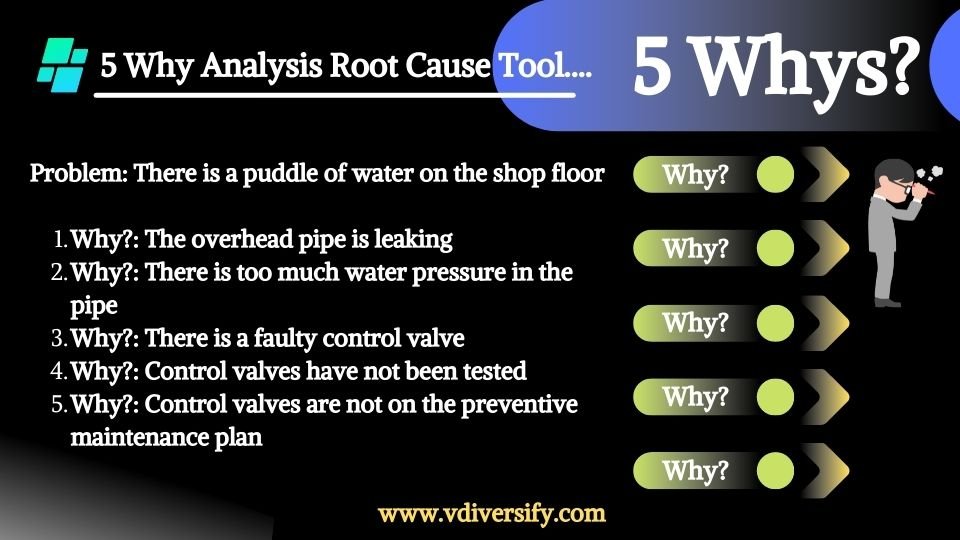

Problem: There is a puddle of water on the shop floor

Why?: The overhead pipe is leaking

Why?: There is too much water pressure in the pipe

Why?: There is a faulty control valve

Why?: Control valves have not been tested

Why?: Control valves are not on the preventive maintenance plan

Root Cause: Control valves are not on the preventive maintenance plan

Example 11:

Problem: One of the advertising agency is facing an acute problem as one of its clients has threatened to pull out the account as there were increase in the deliverables.

Why?: The accounts head didn’t approve the deliverables on time

Why?: The account head was absent for an unplanned 2 days leaves as he was sick

Why?: A substitute account manager was not assigned for the approvals

Why?: There was no contingency plan was made available

Why?: The procedure for contingency plan was missing

Root Cause: The procedure for contingency plan was missing

Example 12:

Problem: Customers wait too long on the phone at the end of the month

Why?: The last week of the month is the busiest for sales

Why?: The company offers more incentives to customers late in the month

Why?: Sales are usually behind the goal late in the month

Why?: Customers have learned that if they wait, they will get incentives

Why?: Sales targets are done on a monthly basis, letting a big deficit form

Root Cause: Sales targets are done on a monthly basis, letting a big deficit form

Example 13:

Problem: Wrong item shipped to customer

Why?: The wrong item was pulled from inventory

Why?: The item we pulled from inventory was mislabeled

Why?: Our supplier mislabeled the item prior to shipping it to our warehouse

Why?: The individual applying labels to our product at the supplier placed the wrong label on the product

Why?: Labels for different orders are pre-printed and it is easy to apply the wrong label

Root Cause: Labels for different orders are pre-printed and it is easy to apply the wrong label

Example 14:

Problem: Material was not reached on time

Why?: The material was dispatched late

Why?: The material was not ready on time

Why?: The specifications of material reached late

Why?: The material specifications was not sent with purchase order

Why?: Purchase person missed to send it together

Root Cause: Gap found in the induction process of new employee for purchase department

Example 15:

Problem: Ashish is often late for work

Why?: He works late into the evenings

Why?: He has a lot of projects on the go

Why?: He leaves things to last minute

Why?: He finds time management challenging

Why?: He struggles to organize his tasks

Root Cause: He struggles to organize his tasks

Example 16:

Problem: Got caught speeding

Why?: Late for work

Why?: Got up late

Why?: Alarm clock didn’t work

Why?: Batteries were flat

Why?: Forgot to replace them

Root Cause: Forgot to replace them

Example 17:

Problem: The robot stopped working suddenly

Why?: The circuit has overloaded, causing a fuse to blow

Why?: There was insufficient lubrication on the bearings, so they locked up

Why?: The oil pump on the robot is not circuiting sufficient oil

Why?: The pump intake is clogged with metal shavings

Why?: Because there is no filter on the pump

Root Cause: Because there is no filter on the pump

Example 18:

Problem: A maintenance tech slip has been raised

Why?: There was an oil leak near the machine

Why?: A seal was deteriorated

Why?: The seal was too weak for its application

Why?: A cheaper seal was purchased

Why?: Service manuals didn’t specify seal type

Root Cause: Service manuals didn’t specify seal type

Example 19:

Problem: The newsletter didn’t go out on time

Why?: Article submissions weren’t submitted on time

Why?: Because the freelancers assignments didn’t go out on time

Why?: Because the freelances are new and hadn’t submitted a signed non-disclosure agreement

Why?: Because they weren’t onboarded properly

Why?: Because the new editing assistant isn’t familiar with the onboarding procedures

Root Cause: Because the new editing assistant isn’t familiar with the onboarding procedures

Example 20:

Problem: A maintenance technician slipped and injured himself during a routine inspection

Why?: There was an oil leak near the machine on which he was working

Why?: A seal in the machine deteriorated, causing cracking and leaked oil

Why?: The seal was not strong enough for the application in which it was being used

Why?: A cheaper seal was purchased from a new supplier

Why?: The type of seal and seal material were not specified in the service manuals

Root Cause: The type of seal and seal material were not specified in the service manuals

Example 21:

Problem: Failure to complete the project within the deadline

Why?: We were short on time to complete 3 modules

Why?: Our deadlines were too harsh

Why?: Our initial effort planning was wrong

Why?: Wrong assumptions of unknowns

Why?: Rushed through the estimation

Why?: Hurry to start

Root Cause: Hurry to start

Example 22:

Problem: Rohan was found falling asleep in class

Why?: Rohan is tired

Why?: Rohan is not getting enough sleep

Why?: Rohan is staying awake too long at night

Why?: Rohan is unable to fall asleep when he goes to bed

Why?: Rohan stays up until late night and keeps on using his phone

Root Cause: Rohan stays up until late night and keeps on using his phone

Example 23:

Problem: Patients don’t attend their doctor appointment

Why?: The appointment message doesn’t alert them before the door session

Why?: The messages don’t have an alert feature

Why?: The system doesn’t allow repeated messages or link appointment to patient’s calendar

Why?: The system doesn’t include an alerting or follow-up feature

Root Cause: The system doesn’t include an alerting or follow-up feature

Example 24:

Problem: Modules not properly grounded

Why?: Ground clip not secured properly

Why?: Clip was deformed

Why?: Clip was reused on module installation

Why?: Insufficient quantity of clips were available in truck

Why?: Only the specified number of clips needed for install were stocked on truck

Root Cause: Only the specified number of clips needed for install were stocked on truck

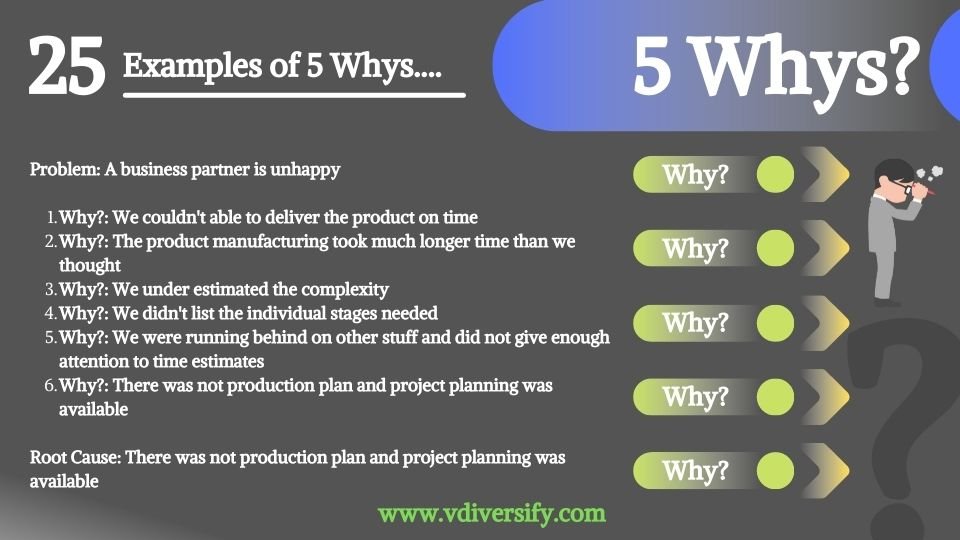

Example 25:

Problem: A business partner is unhappy

Why?: We couldn’t able to deliver the product on time

Why?: The product manufacturing took much longer time than we thought

Why?: We under estimated the complexity

Why?: We didn’t list the individual stages needed

Why?: We were running behind on other stuff and did not give enough attention to time estimates

Why?: There was not production plan and project planning was available

Root Cause: There was not production plan and project planning was available

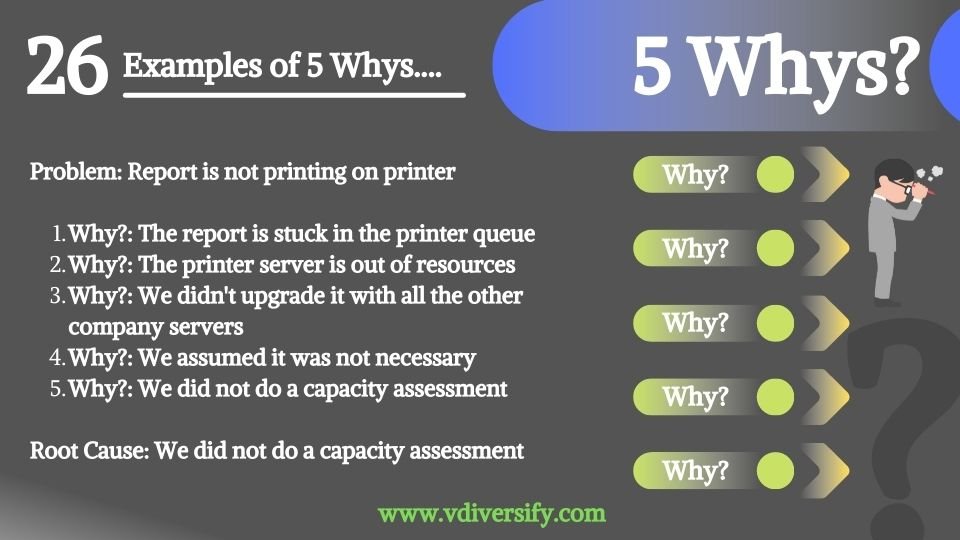

Example 26:

Problem: Report is not printing on printer

Why?: The report is stuck in the printer queue

Why?: The printer server is out of resources

Why?: We didn’t upgrade it with all the other company servers

Why?: We assumed it was not necessary

Why?: We did not do a capacity assessment

Root Cause: We did not do a capacity assessment

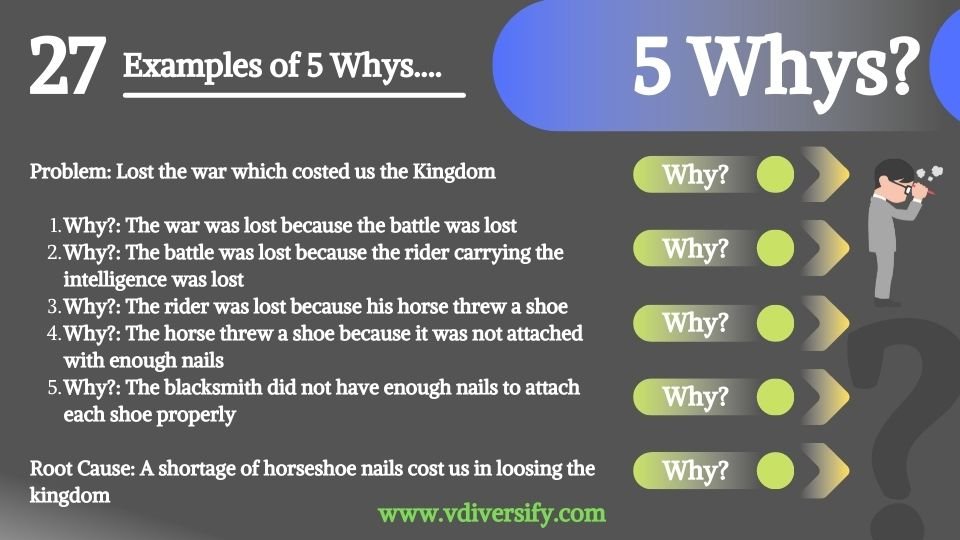

Example 27:

Problem: Lost the war which costed us the Kingdom

Why?: The war was lost because the battle was lost

Why?: The battle was lost because the rider carrying the intelligence was lost

Why?: The rider was lost because his horse threw a shoe

Why?: The horse threw a shoe because it was not attached with enough nails

Why?: The blacksmith did not have enough nails to attach each shoe properly

Root Cause: A shortage of horseshoe nails cost us in loosing the kingdom

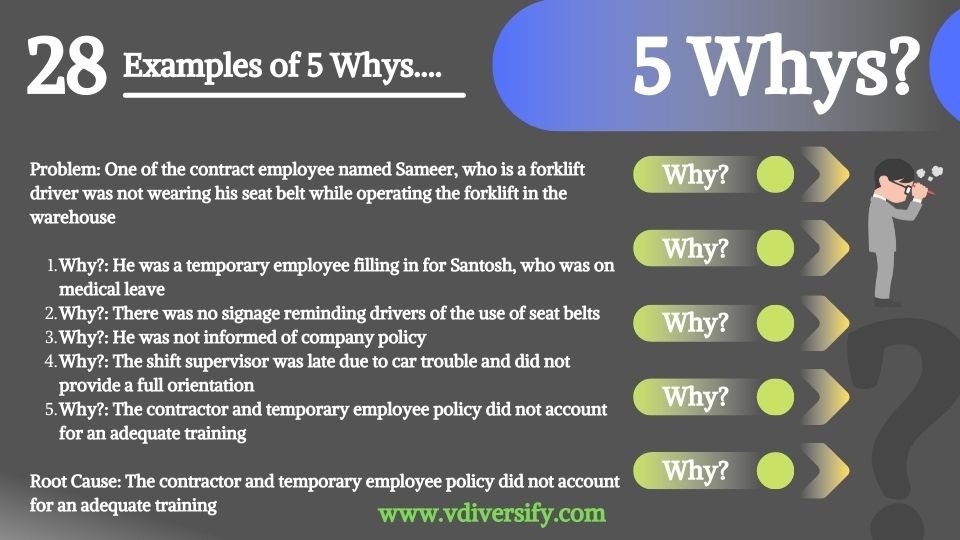

Example 28:

Problem: One of the contract employee named Sameer, who is a forklift driver was not wearing his seat belt while operating the forklift in the warehouse

Why?: He was a temporary employee filling in for Santosh, who was on medical leave

Why?: There was no signage reminding drivers of the use of seat belts

Why?: He was not informed of company policy

Why?: The shift supervisor was late due to car trouble and did not provide a full orientation

Why?: The contractor and temporary employee policy did not account for an adequate training

Root Cause: The contractor and temporary employee policy did not account for an adequate training

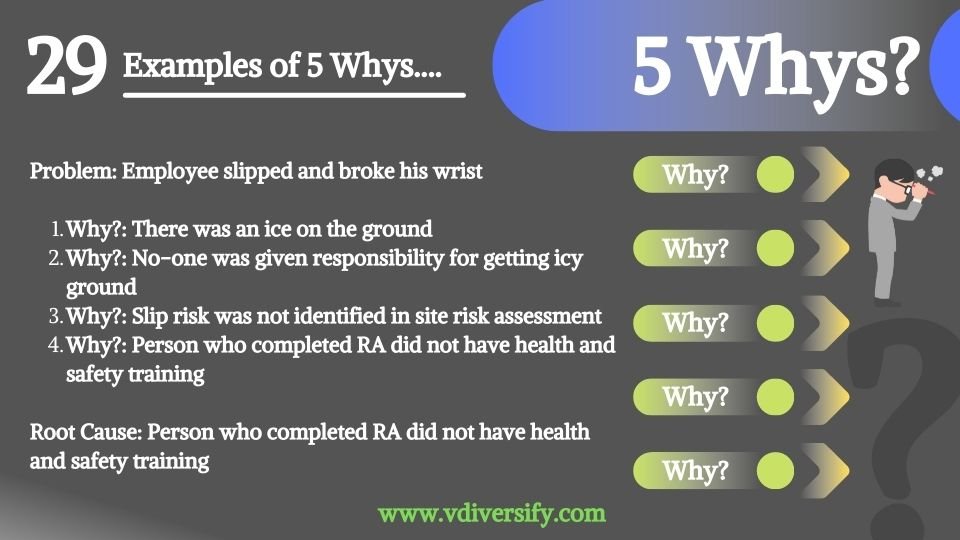

Example 29:

Problem: Employee slipped and broke his wrist

Why?: There was an ice on the ground

Why?: No-one was given responsibility for getting icy ground

Why?: Slip risk was not identified in site risk assessment

Why?: Person who completed RA did not have health and safety training

Root Cause: Person who completed RA did not have health and safety training

Example 30:

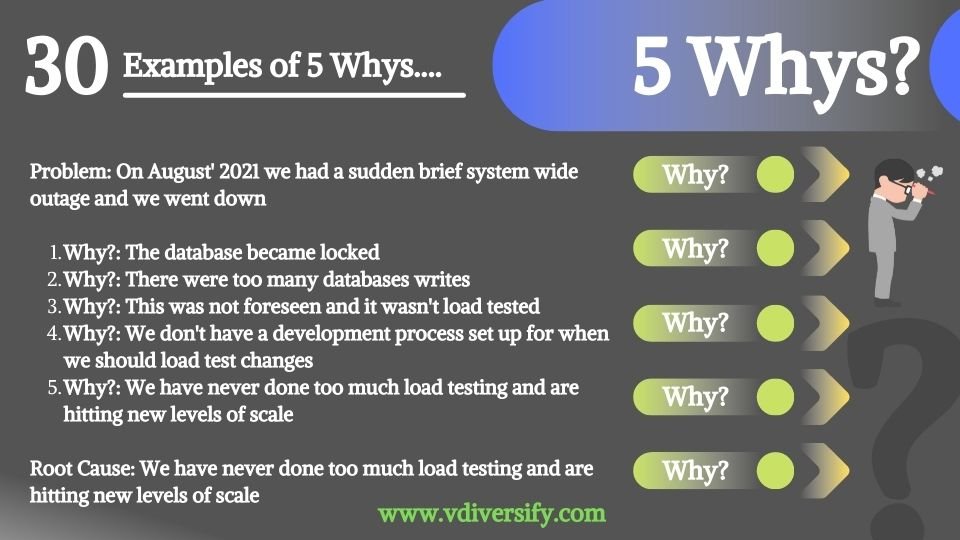

Problem: On August’ 2021 we had a sudden brief system wide outage and we went down

Why?: The database became locked

Why?: There were too many databases writes

Why?: This was not foreseen and it wasn’t load tested

Why?: We don’t have a development process set up for when we should load test changes

Why?: We have never done too much load testing and are hitting new levels of scale

Root Cause: We have never done too much load testing and are hitting new levels of scale

Example 31:

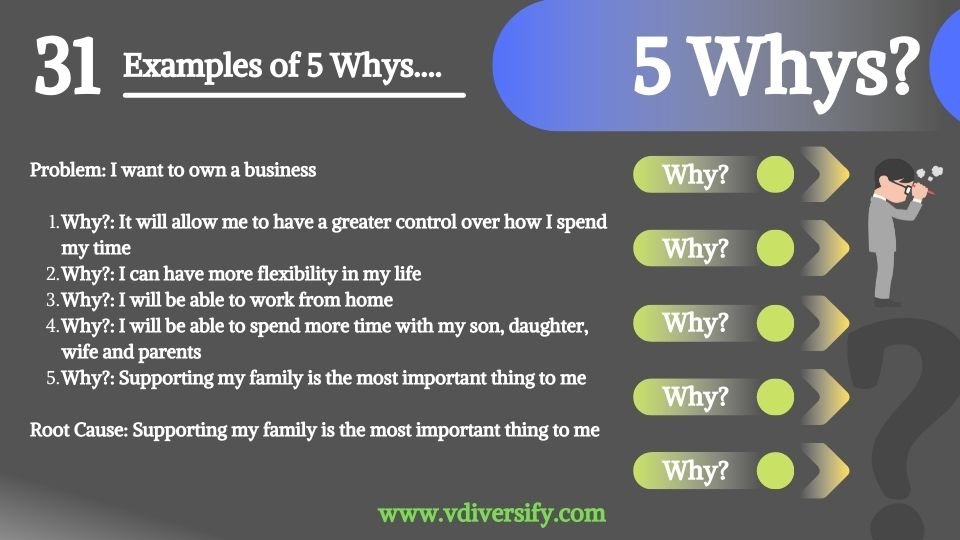

Problem: I want to own a business

Why?: It will allow me to have a greater control over how I spend my time

Why?: I can have more flexibility in my life

Why?: I will be able to work from home

Why?: I will be able to spend more time with my son, daughter, wife and parents

Why?: Supporting my family is the most important thing to me

Root Cause: Supporting my family is the most important thing to me

Example 32:

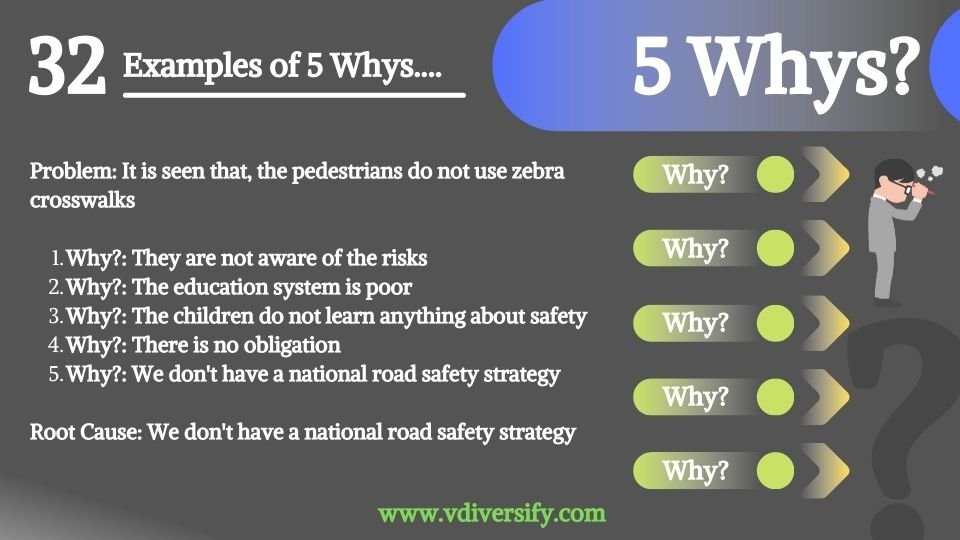

Problem: It is seen that, the pedestrians do not use zebra crosswalks

Why?: They are not aware of the risks

Why?: The education system is poor

Why?: The children do not learn anything about safety

Why?: There is no obligation

Why?: We don’t have a national road safety strategy

Root Cause: We don’t have a national road safety strategy

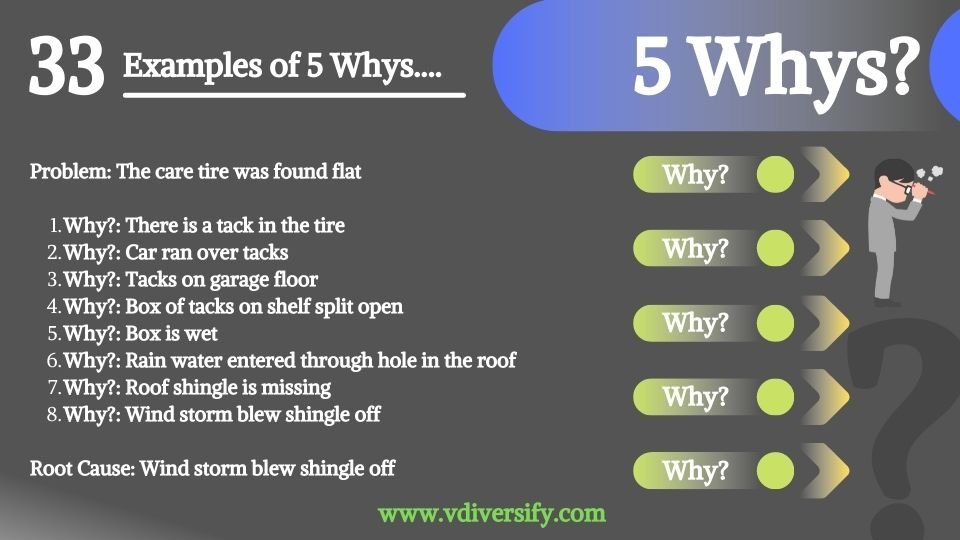

Example 33:

Problem: The care tire was found flat

Why?: There is a tack in the tire

Why?: Car ran over tacks

Why?: Tacks on garage floor

Why?: Box of tacks on shelf split open

Why?: Box is wet

Why?: Rain water entered through hole in the roof

Why?: Roof shingle is missing

Why?: Wind storm blew shingle off

Root Cause: Wind storm blew shingle off

Example 34:

Problem: The care tire was found flat

Why?: There is a tack in the tire

Why?: Car ran over tacks

Why?: Tacks on garage floor

Why?: Box of tacks on shelf split open

Why?: Box is wet

Why?: Rain water entered through hole in the roof

Why?: Roof shingle is missing

Why?: Wind storm blew shingle off

Root Cause: Wind storm blew shingle off

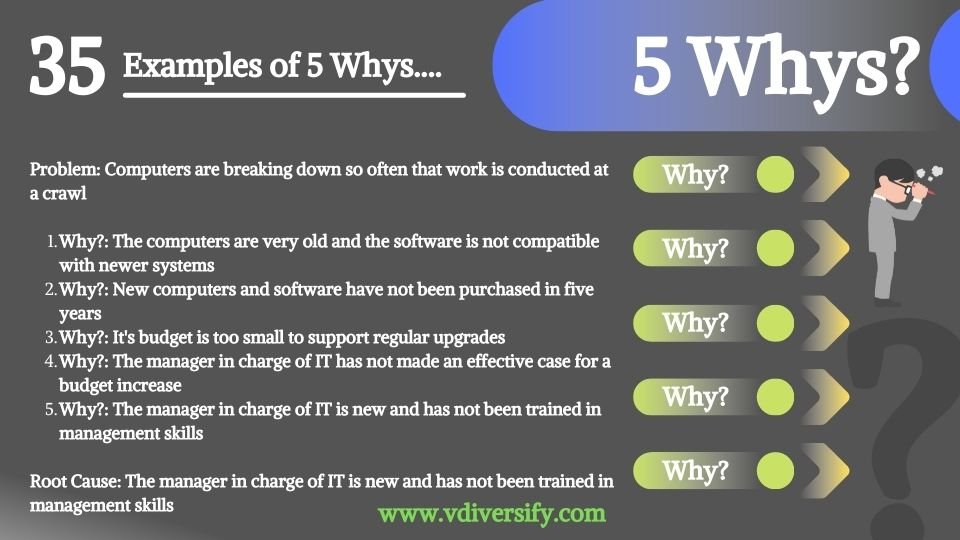

Example 35:

Problem: Computers are breaking down so often that work is conducted at a crawl

Why?: The computers are very old and the software is not compatible with newer systems

Why?: New computers and software have not been purchased in five years

Why?: It’s budget is too small to support regular upgrades

Why?: The manager in charge of IT has not made an effective case for a budget increase

Why?: The manager in charge of IT is new and has not been trained in management skills

Root Cause: The manager in charge of IT is new and has not been trained in management skills

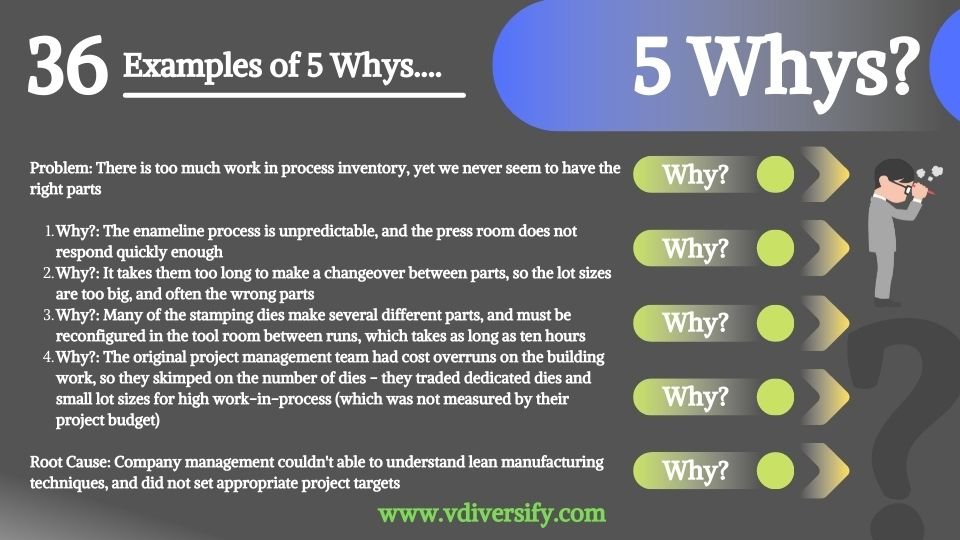

Example 36:

Problem: There is too much work in process inventory, yet we never seem to have the right parts

Why?: The enameline process is unpredictable, and the press room does not respond quickly enough

Why?: It takes them too long to make a changeover between parts, so the lot sizes are too big, and often the wrong parts

Why?: Many of the stamping dies make several different parts, and must be reconfigured in the tool room between runs, which takes as long as ten hours

Why?: The original project management team had cost overruns on the building work, so they skimped on the number of dies – they traded dedicated dies and small lot sizes for high work-in-process (which was not measured by their project budget)

Root Cause: Company management couldn’t able to understand lean manufacturing techniques, and did not set appropriate project targets

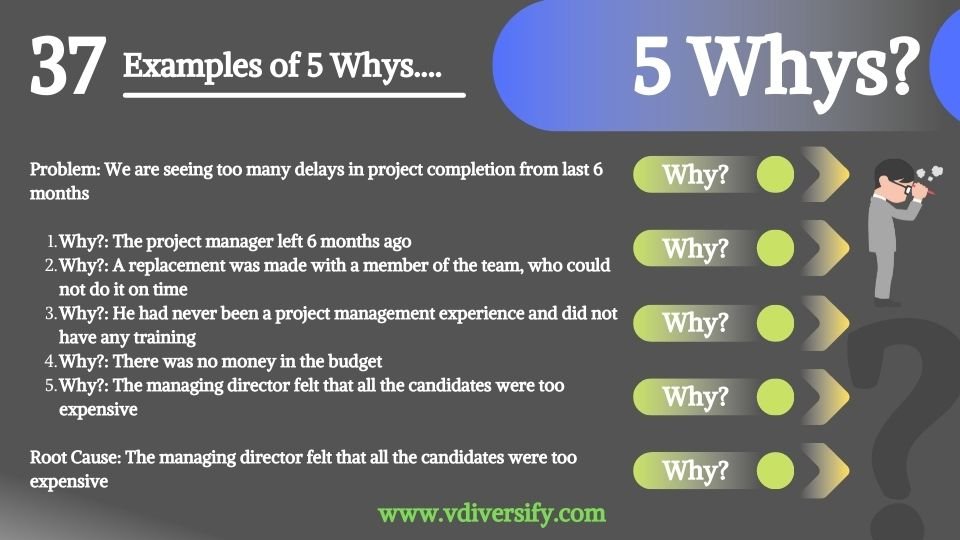

Example 37:

Problem: We are seeing too many delays in project completion from last 6 months

Why?: The project manager left 6 months ago

Why?: A replacement was made with a member of the team, who could not do it on time

Why?: He had never been a project management experience and did not have any training

Why?: There was no money in the budget

Why?: The managing director felt that all the candidates were too expensive

Root Cause: The managing director felt that all the candidates were too expensive

Example 38:

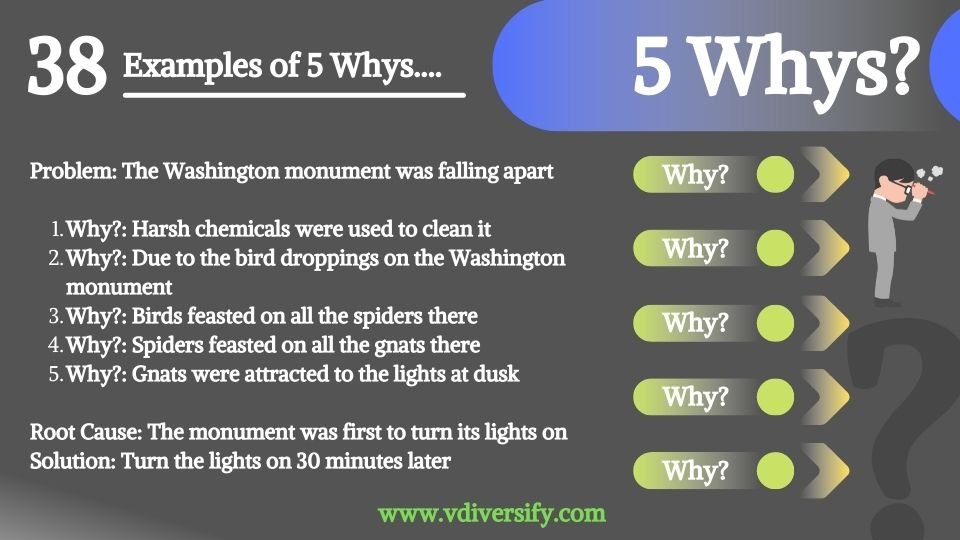

Problem: The Washington monument was falling apart

Why?: Harsh chemicals were used to clean it

Why?: Due to the bird droppings on the Washington monument

Why?: Birds feasted on all the spiders there

Why?: Spiders feasted on all the gnats there

Why?: Gnats were attracted to the lights at dusk

Root Cause: The monument was first to turn its lights on

Solution: Turn the lights on 30 minutes later

Example 39:

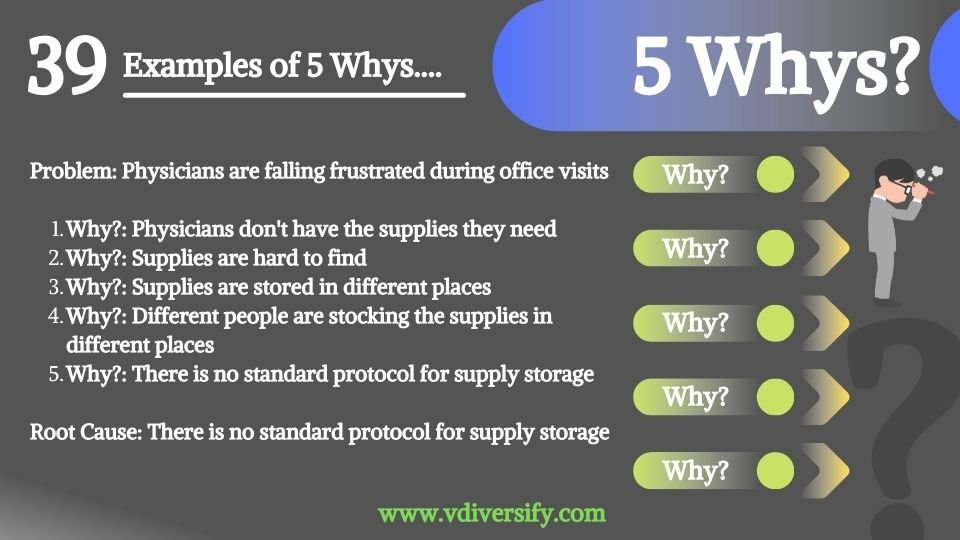

Problem: Physicians are falling frustrated during office visits

Why?: Physicians don’t have the supplies they need

Why?: Supplies are hard to find

Why?: Supplies are stored in different places

Why?: Different people are stocking the supplies in different places

Why?: There is no standard protocol for supply storage

Root Cause: There is no standard protocol for supply storage

Example 40:

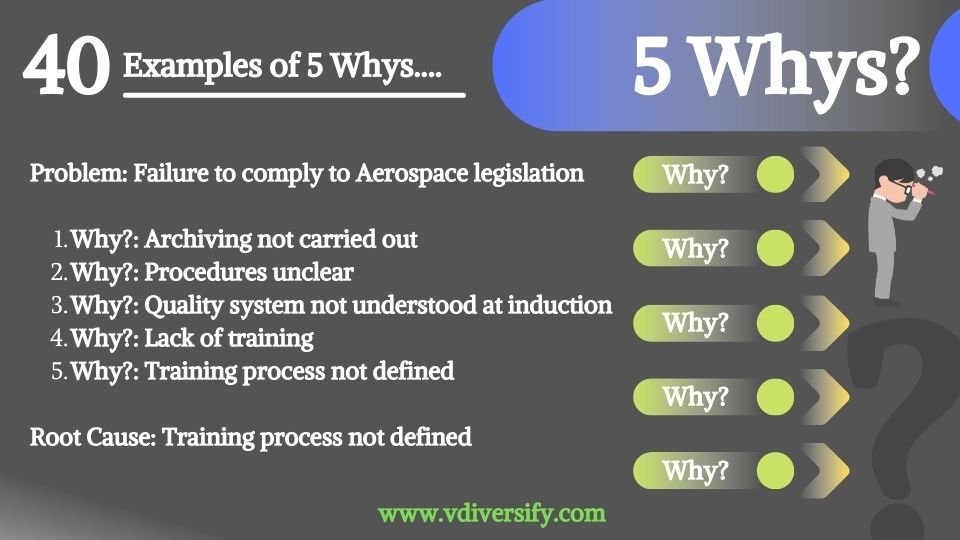

Problem: Failure to comply to Aerospace legislation

Why?: Archiving not carried out

Why?: Procedures unclear

Why?: Quality system not understood at induction

Why?: Lack of training

Why?: Training process not defined

Root Cause: Training process not defined

Example 41:

Problem: Did not meet the annual business plan goal of a 10% increase in sales

Why?: Did not thoroughly evaluate market or competition

Why?: Did not have adequate resources

Why?: Did not anticipate required resources

Why?: Did not develop a plan as to how the goal would be reached

Root Cause: Did not develop a plan as to how the goal would be reached

Example 42:

Problem: The machine stopped because it overloaded and the fuse blew

Why?: The bearing wasn’t being sufficiently lubricated

Why?: Lubrication mechanism had a pump which was not pumping sufficiently

Why?: The pump had a worn shaft

Why?: There is not an adequate mechanism in place to prevent metal scraps getting into the pump and damaging it

Root Cause: There is not an adequate mechanism in place to prevent metal scraps getting into the pump and damaging it

Example 43:

Problem: The villagers of one of the village are unhappy

Why?: We did not deliver our services when we said we would

Why?: The start up took much longer than we thought it would

Why?: We had no staff at the planned start date

Why?: Our work plan did not have time specifically for recruitment

Why?: Those who wrote the plan don’t know the recruitment problems

Root Cause: Those who wrote the plan don’t know the recruitment problems

Example 44:

Problem: One of the drilling machine stopped suddenly

Why?: Overload tripped out

Why?: Insufficient oil on shaft

Why?: Oil pump in-efficient

Why?: Pump drive shaft worn

Why?: Oil filter blocked with swarf

Root Cause: Oil filter blocked with swarf

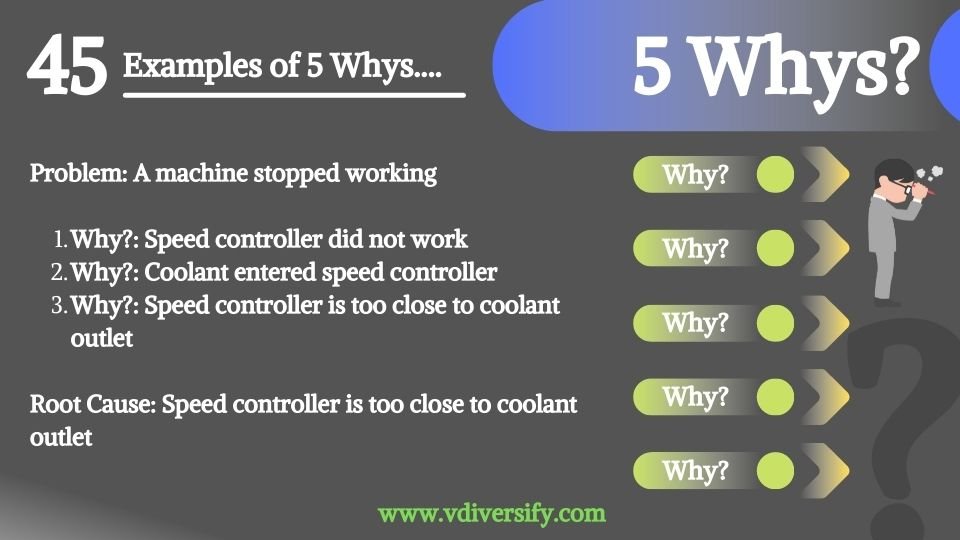

Example 45:

Problem: A machine stopped working

Why?: Speed controller did not work

Why?: Coolant entered speed controller

Why?: Speed controller is too close to coolant outlet

Root Cause: Speed controller is too close to coolant outlet

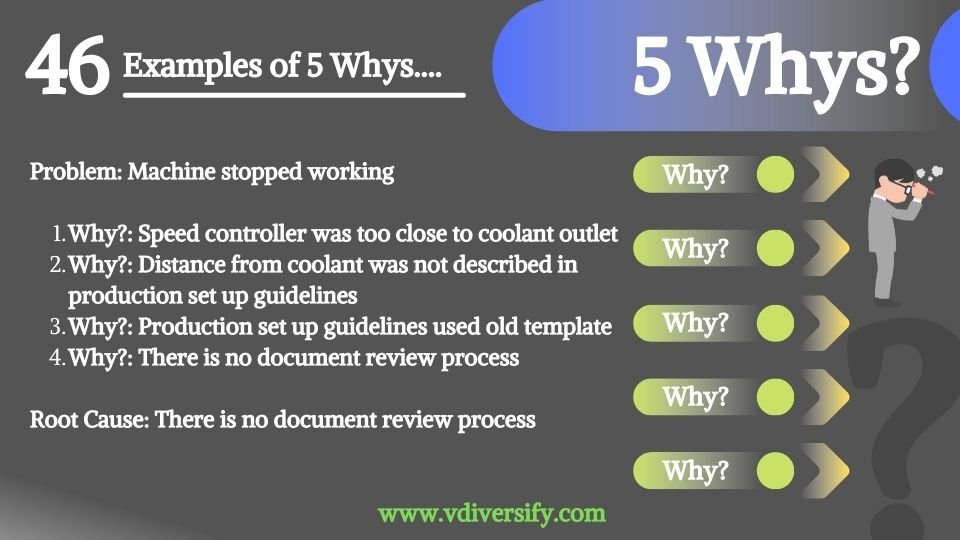

Example 46:

Problem: Machine stopped working

Why?: Speed controller was too close to coolant outlet

Why?: Distance from coolant was not described in production set up guidelines

Why?: Production set up guidelines used old template

Why?: There is no document review process

Root Cause: There is no document review process

Example 47:

Problem: Law firm loss in legal directory

Why?: The firm has projects that are weaker than competitors

Why?: One of the leading partners has been fired

Why?: The projects have lower transaction value

Why?: Managing partners have a strong brand on the market

Root Cause: Managing partners have a strong brand on the market

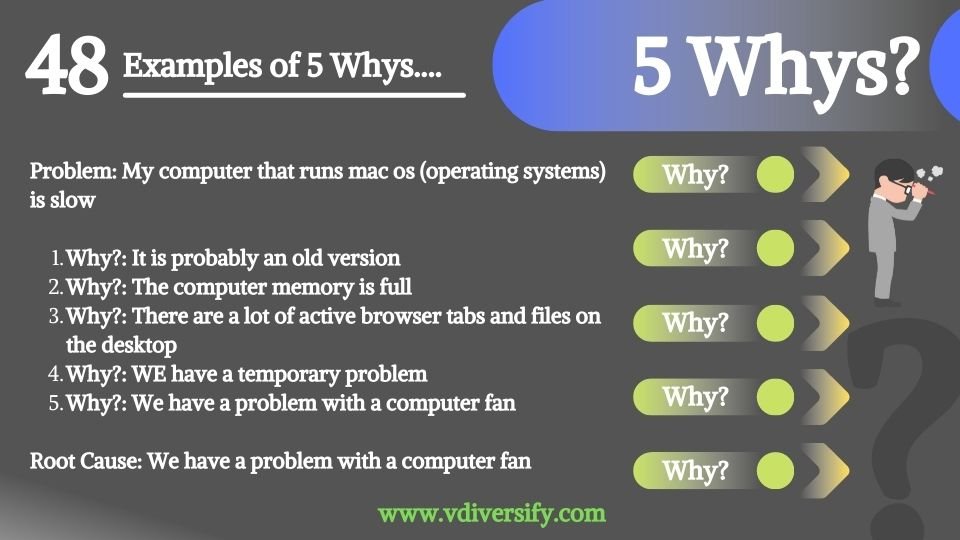

Example 48:

Problem: My computer that runs Mac OS (operating systems) is slow

Why?: It is probably an old version

Why?: The computer memory is full

Why?: There are a lot of active browser tabs and files on the desktop

Why?: WE have a temporary problem

Why?: We have a problem with a computer fan

Root Cause: We have a problem with a computer fan

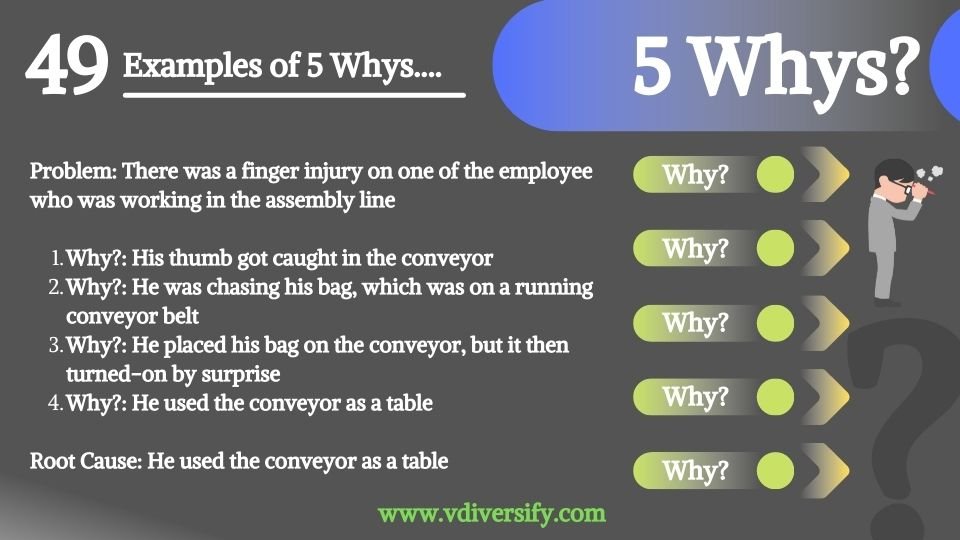

Example 49:

Problem: There was a finger injury on one of the employee who was working in the assembly line

Why?: His thumb got caught in the conveyor

Why?: He was chasing his bag, which was on a running conveyor belt

Why?: He placed his bag on the conveyor, but it then turned-on by surprise

Why?: He used the conveyor as a table

Root Cause: He used the conveyor as a table

Example 50:

Problem: I want to go to graduate school

Why?: I need to in order to be an SEO expert

Why?: I enjoy doing original research to learn about the past

Why?: I like crafting a problem and figuring out methods to solve it

Why?: I like knowing all the wants you could solve a problem

Why?: It makes me feel like an indispensable expert

Root Cause: It makes me feel like an indispensable expert

Example 51:

Problem: My motorcycle is not starting

Why?: The battery is dead

Why?: The alternator is not functioning

Why?: The alternator belt has broken

Why?: The alternators belt was well beyond its useful service life and not replaced

Why?: The vehicle was not maintained according to the recommended service schedule

Root Cause: The vehicle was not maintained according to the recommended service schedule

Example 52:

Problem: The customer is complaining about the service

Why?: The customer order took too long

Why?: There was a bottleneck in the kitchen

Why?: The current orders exceed the kitchen’s capacity

Why?: Not enough people schedule for the kitchen at this time, nobody is trained to help

Why?: There is no standard work or cross training

Root Cause: There is no standard work or cross training

Example 53:

Problem: My tea is cold when I prepared tea on a kettle

Why?: The kettle didn’t heat the water

Why?: No power. The fuse in the plug was blown

Why?: An incorrect rated fuse was fitted

Why?: The required fuse was not specified

Why?: There was no specification for fuses

Root Cause: There was no specification for fuses

Example 54:

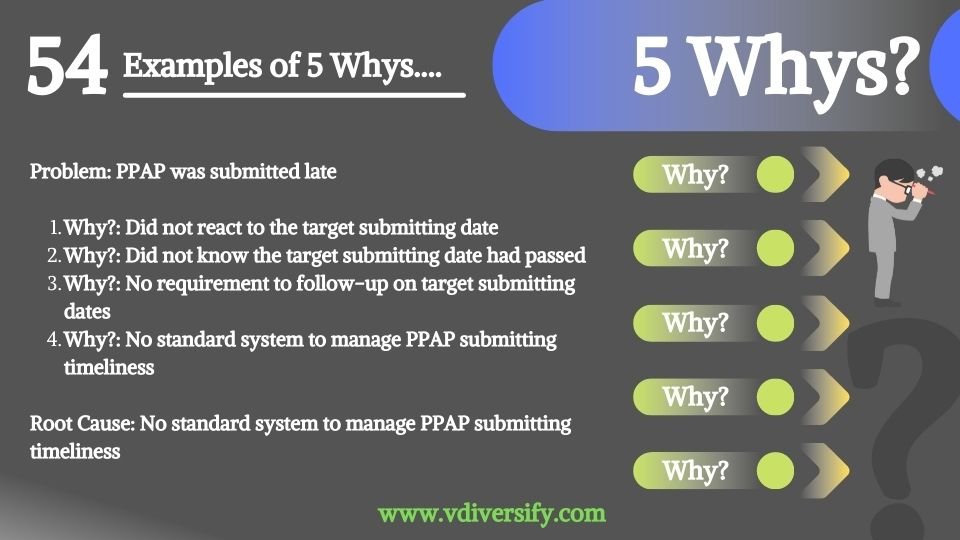

Problem: PPAP was submitted late

Why?: Did not react to the target submitting date

Why?: Did not know the target submitting date had passed

Why?: No requirement to follow-up on target submitting dates

Why?: No standard system to manage PPAP submitting timeliness

Root Cause: No standard system to manage PPAP submitting timeliness

Example 55:

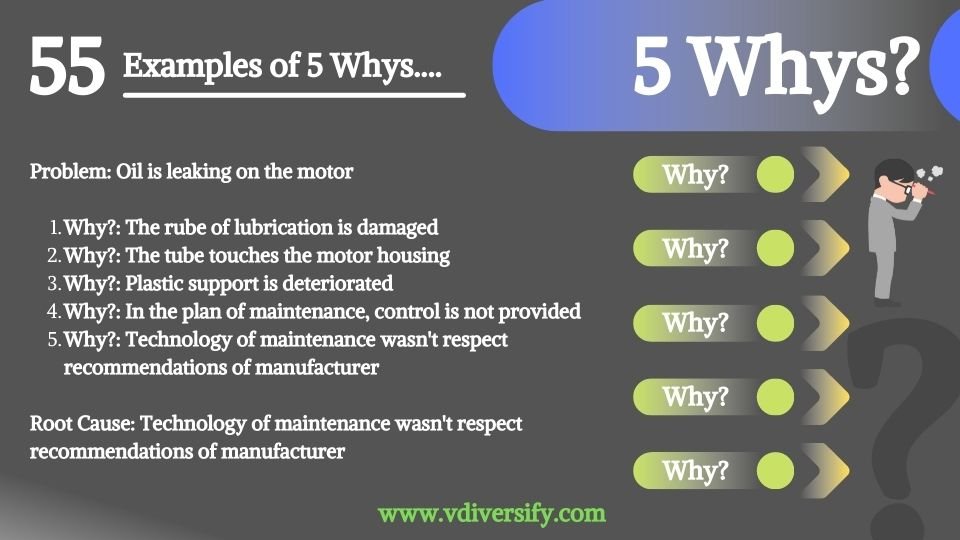

Problem: Oil is leaking on the motor

Why?: The rube of lubrication is damaged

Why?: The tube touches the motor housing

Why?: Plastic support is deteriorated

Why?: In the plan of maintenance, control is not provided

Why?: Technology of maintenance wasn’t respect recommendations of manufacturer

Root Cause: Technology of maintenance wasn’t respect recommendations of manufacturer

Example 56:

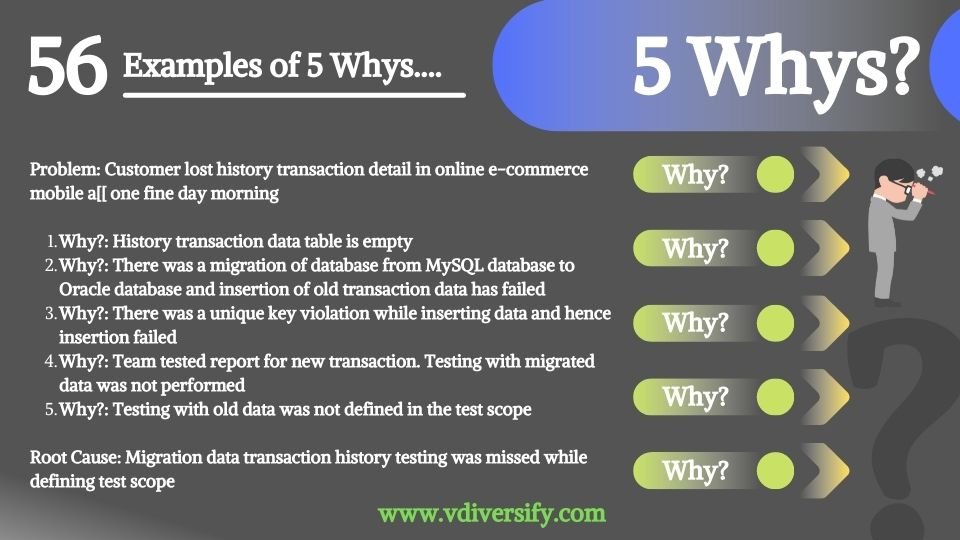

Problem: Customer lost history transaction detail in online e-commerce mobile a[[ one fine day morning

Why?: History transaction data table is empty

Why?: There was a migration of database from MySQL database to Oracle database and insertion of old transaction data has failed

Why?: There was a unique key violation while inserting data and hence insertion failed

Why?: Team tested report for new transaction. Testing with migrated data was not performed

Why?: Testing with old data was not defined in the test scope

Root Cause: Migration data transaction history testing was missed while defining test scope

Example 57:

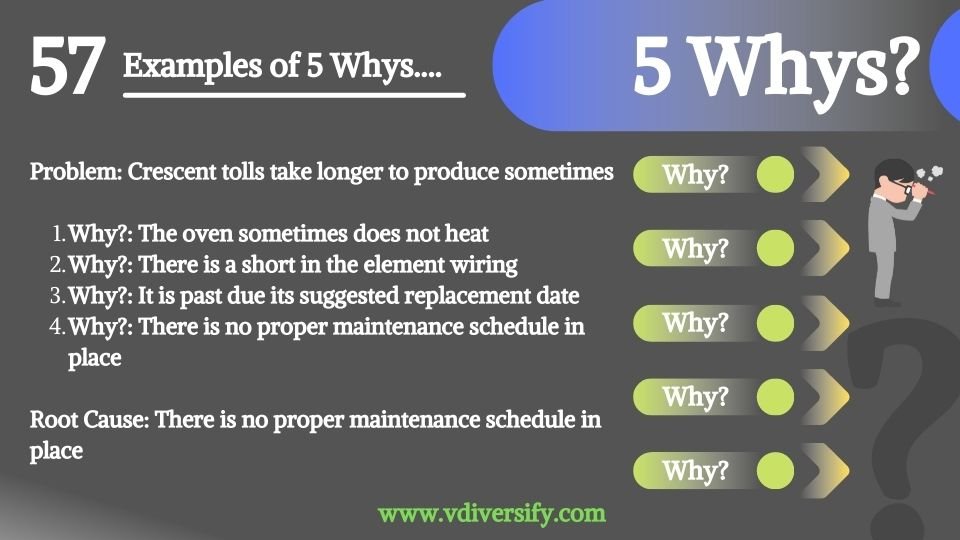

Problem: Crescent tolls take longer to produce sometimes

Why?: The oven sometimes does not heat

Why?: There is a short in the element wiring

Why?: It is past due its suggested replacement date

Why?: There is no proper maintenance schedule in place

Root Cause: There is no proper maintenance schedule in place

5 Why Analysis PDF and 5 Why Analysis Examples – Download Here

5 why analysis pdf:

The 5 why analysis is the best problem solving tool to find out the exact root cause of a problem. If you are looking for an in-depth 5 why analysis template or a 5 why analysis pdf, then you can download it from the links below. This 5 why pdf also contains 57 examples across various businesses and industries that are best 5 why analysis examples that you can refer, learn, and implement. You can download,

- 5 why analysis pdf

- 5 why analysis template

- 5 why analysis examples

Download: 5 why analysis pdf here >>>

Download: 5 why analysis template here >>>

Download: 5 why analysis excel template here >>>

Conclusion

The 5 why analysis root cause tool is the best problem solving tool that helps to solve problems effectively. No matter which business you run or industry you are in, the 5 why technique is the effective tools of problem solving. In simple terms, the 5 why why analysis is finding the right root cause by asking why questions at-least 5 times.

The 5 why analysis has the following advantages:

- The 5 whys method helps the CFT to find the exact root cause of any kind of problem

- The 5 why technique effectively solves a problem by each individual contributing to solve a problem by sharing ideas for continual improvement, rather than just blaming each others

- The 5 whys tool helps the CFT to eliminate any problem more confidently and prevents the problem from recurring or stops creating failures again and again

- The 5 whys helps to improve the processes and systems by implementing more and more continual improvement programs

- Understand and analyze how one process can cause a chain of problems

- Determine the relationship between multiple probable causes or multiple root causes

- Easy to use tool which is a non-statistical problem solving method

“Hey, I am Sachin Ramdurg, the founder of VDiversify.com.

I am an Engineer and Passionate Blogger with a mindset of Entrepreneurship. I have been experienced in Blogging for more than 15+ years and following as a youtuber along with blogging, online business ideas, affiliate marketing, and make money online ideas since 2012.

4 thoughts on “5 Why Analysis Root Cause [2022] – The Ultimate Problem Solving Tool”